Cyclingnews Verdict

Roval says they are setting a new standard in tubeless safety but no matter where you stand on that you still get a lightning-fast wheelset that’s incredibly comfortable and sticks to a hooked bead for tyre choice.

Pros

- +

Tubeless compatible

- +

Hooked bead makes for better tyre compatibility

- +

Fast wheels

- +

“**it Happens” No Fault Crash Replacement Policy

Cons

- -

Pro rider first mentality means a 26mm centric design

You can trust Cyclingnews

Over and over, you've heard the advice that the single biggest upgrade you can make to a frame is a new wheelset. The reason for that isn't that the wheelset you have is bad, it's that it's not yours. In the past wheels were wheels and you'd want to upgrade for better quality. Today the base level is already really good but you have an opportunity to match your riding style to a type of wheel. If you take a look at our list of the best road bike wheels you'll see that diversity reflected in the list.

For those looking for a fast, deep, aerodynamically optimised option, one product on the list is the Roval Rapide CLX. Notably, those wheels have one major drawback. They came to market without tubeless compatibility. It wasn't years ago either, in 2020 when road tubeless had already very much entered the mainstream, Roval brought their flagship aero model to market without tubeless compatibility. It turns out there's a story behind why, and we've now spent time with the almost identical, tubeless compatible second iteration, the Roval Rapide CLX II.

If you are curious to hear how this tale of last-minute product changes and new standard suggestions came to be, keep reading. It's also worth mentioning that whatever history there is, the Roval Rapide CLX II is the current offering. That means if you are looking for a new set of ultra-fast wheels it's worth continuing to read just to see what we think of the Roval offering compared to the competition.

Roval's journey to tubeless acceptance

The history

According to Roval, the Rapide CLX II wheelset is the fastest wheelset that it has ever made. However, they use the exact same external rim shape, spoke patterns, and hub as the previous generation, so what is going on?

It comes down to one thing, tubeless compatibility. Roval claims that tubeless wheels are faster than tube type and the new wheels are tubeless compatible while the previous generation was not. Being fair to Roval, it isn't alone in the claim of tubeless being faster. Industry-wide there is agreement that tubeless wheel systems offer a faster ride. If all you care about is the stopwatch, there's less rolling resistance. For most people though, the benefits of tubeless go way beyond the stopwatch and the rarity of flat tyres paired with the possibility of running lower pressures make tubeless the better choice regardless of their race performance.

So, if Roval claims tubeless is faster, and the industry agrees, why was the previous generation not tubeless? Those wheels aren't ancient history, they only came out two years ago, what changed? The answer is that the previous generation had a design meant to be tubeless compatible but they didn't come to market that way.

The trajectory of a major product shifted because of Peter Sagan. You could take that as the cycling industry being really small, it is, or Peter Sagan being highly influential, he is, but either way, one man shifted a major product and it's taken two years to address the issue. At the end of 2019 during final testing, Peter Sagan hopped a curb with the ready to ship set of Roval Alpinist CLX wheels his team had been testing. There's no doubt that Sagan is an amazing bike handler but he makes mistakes too. In this case that meant a missed landing.

As the wheel slammed into the curb the rim bed, and the pressure envelope, cracked. In this situation, it's expected that the tyre will pinch flat and instantly lose pressure. What isn't expected is that the resulting pressure equalisation causes the side of the wheel to blow out and the tyre to come off the wheel. There are specific tests designed to make sure that tubeless wheels and tyres fail in expected ways and that's not what happened. Roval had passed the tests but at the last minute, a real-world "test" had yielded a different result and now the brand had to decide what to do.

The first step in the process was to pull the wheels back and start redesigning them. The smallness of the industry played out again though. In this case, it actually had a lot to do with how much a WorldTour race performance driven company Roval is. The generation of wheels that were about to go to market had been in testing with sponsored teams and they were faster. None of the riders wanted to go back to the slower wheels, so rather than pull the wheels completely the decision was to mark them as tube type only. At the point they went to market, the first generation of Rapide and Alpinist wheels were the fastest wheels Roval had ever made and they went on to win, a lot.

The challenge

What do tubes actually have to do with wheel integrity? Why does it matter if a wheel is tubeless if you smack it against a curb at full speed? It's from here that the team behind the Roval wheels had to start researching. Even tubeless wheels generally get tested with tubes in them. It's easier and more repeatable and no one considered it an issue. What Roval found is that when there's a tube in a tyre it slows the release of pressure just enough that it can save a wheel from failing in a dangerous manner.

All wheels will fail if you hit them hard enough. The question becomes where is the line for an expected failure and in what way does it happen. Specifically, with tubeless, you've got a pressure vessel created with the rim tape, rim bed, and the tyre. Now, how hard do you have to hit that pressure vessel to cause failure and when failure happens, how does it happen? It turns out there's a slight difference when there's a tube in the equation vs when there's not. The tiny bit of extra material changes things and Roval had to go back to the drawing board.

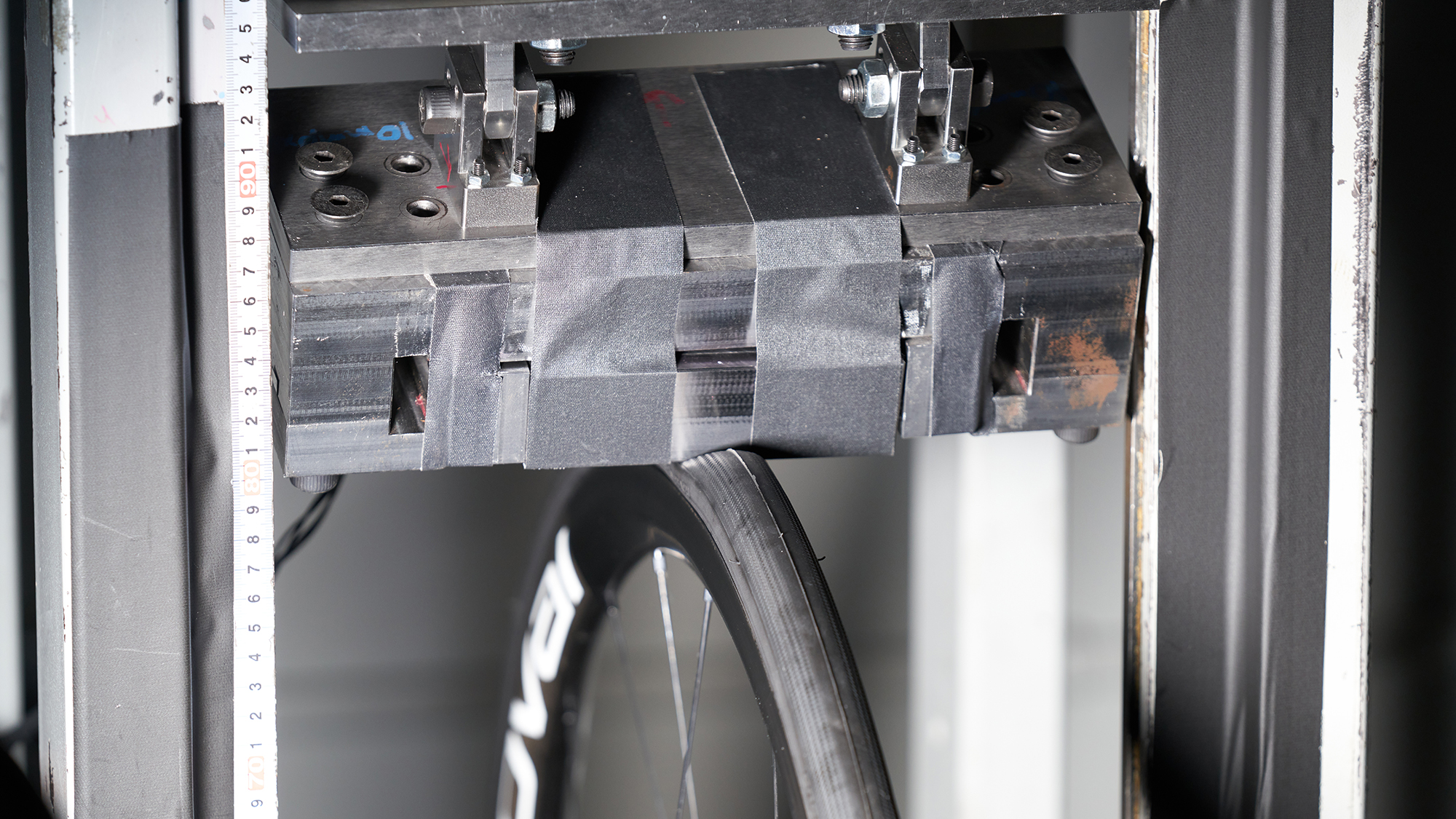

In the midst of a global pandemic and economic shutdown, the team at Roval had to not only redesign a set of wheels that they considered their best work but also redesign every testing protocol the industry relied on. Over the course of the project the team tested thousands of rim designs and hundreds of different carbon layups. The first step though was to understand the limits of reasonable failure. The solution here is worth sharing just because of what the team asked people to do. They took a square steel block with sensors, bolted it to the ground, and then rode full speed into it.

The testing looks as crazy as it sounds but it provided the real-world numbers the team needed. With those numbers in hand, they then took the same block and used it on impact sleds. The testing Roval was doing differed from previous tests in that it used a sharp edge that concentrated impact in a small spot and it was being done with a tyre and without a tube. It was also much higher energy than the traditional 40 joule mandated test. After all that testing, Roval is now ready to bring a revised version of the Rapide CLX, and Alpinist CLX, to market as the Rapid and Alpinist CLX II.

Doesn’t every other brand have this figured out?

The backstory of how Roval found itself with a non-tubeless wheel coming to market in 2020 makes for a nice story but it poses an obvious question. Roval isn't alone in the market, and they aren't the only ones creating tubeless compatible wheels, so why are they the only ones with an issue? There are a couple of sides to that answer.

Engineering is all about iterating over and over to create the absolute best design you can, within limits. Some of those limits might be market based. If the Roval wheels cost double the price to save 50 grams that might not be a workable option. The other part of the equation is that the industry has come to some agreements as to what is a reasonable impact limit. The UCI impact test stipulates a 40-joule impact against a wheel with no tyre and lays out the exact design of the striker as well as what acceptable outcomes are.

It's the limits that matter. We all understand that failures will happen and you can't engineer a solution to everything. Parameters are the guide rails and a good engineering team will get as close to those guide rails as possible without going over. That's exactly what Roval was doing.

The team wanted the lightest possible wheel that still met the limits. The previous generation of Roval wheels passed the tests that set the limits, but they still failed in a way Roval found unacceptable, so after 21 months of research, the team thinks the testing is inadequate. With that in mind, Roval has "proposed these new standards to the relevant governing bodies so all riders can benefit from the work we’ve done."

The other big part of the discussion is what Roval considers a reasonable solution. Most brands have moved to a hookless bead as a way to solve the challenges of tubeless strength and weight. It's a solution that we often cite as a positive quality in our reviews, as it makes a lighter, stronger, rim that's easier and cheaper to manufacture. Roval sees it as a negative though and took it off the table as a solution. They believe that the limits of tyres and pressures which hookless imposes on the end-user isn't a valid solution. Just adding more carbon is another solution but it's also one that Roval considers untenable.

So the answer to the original question is somewhere along the lines of: Other brands haven't actually figured it out. Or at least, that's Roval's opinion.

That is not the same as saying that other brands have unsafe wheels. It's just that Roval wanted to get to a very specific endpoint that not every brand is trying to get to. Other brands have arrived at the end result of a lightweight, safe, wheel by making different choices.

Roval also thinks that there should be updates to the testing standards. It has proposed new testing standards to the relevant governing bodies because it thinks there is room for improvement when it comes to tubeless wheels.

Again, that's not to say that other brands have unsafe wheels. The discovery is that “tubeless wheel systems have a different failure mode. Cracks in the rim bed could propagate to the rim cavity, and the resulting air pressure creates a failure of the entire system. Repeating the same test with a tube results in lower damage levels. The tube throttles the event over a slightly longer time frame by distributing pressure over cracks and delaying pressure release.”

Meaning, it's possible to design a wheel that's not safe but still passes the agreed-upon tests. The tests are only the final guide rail so an update makes sense but it’s not a commentary on what other brands are doing.

Roval Rapide CLX II review

Design and aesthetics

The Roval Rapide CLX II is almost exactly the same wheel as the Roval Rapide CLX. The big headline is obviously that you've now got full tubeless compatibility but the change meant adding a bit of weight. This new generation brings about 50 grams per wheel for a total claimed weight of 1505g for the wheelset. For the Alpinist, an update to the hub shaved some of the weight increase but for the Rapide, the hub remains the same Aeroflange hubs with DT Swiss’ latest Ratchet EXP freehub and ceramic SINC bearings.

There's also a small change to the outer diameter of the wheel to create a little more bead slack. Both designs fell within ETRTO standards but there's a range of what's acceptable. In this case, Roval felt that shrinking the diameter of the wheels, where the bead sits, by 1.4mm, made life a little easier.

Otherwise, these are the same wheels you may have heard about previously. The design revolves around a 26mm tyre width in an effort to keep professional riders using the system in the fastest configuration. There's a 21mm internal width with a front wheel that's 35mm wide externally and 51mm deep. At the rear, the wheel profile is a little more like a traditional "V" with a 30mm external width and a depth of 60mm.

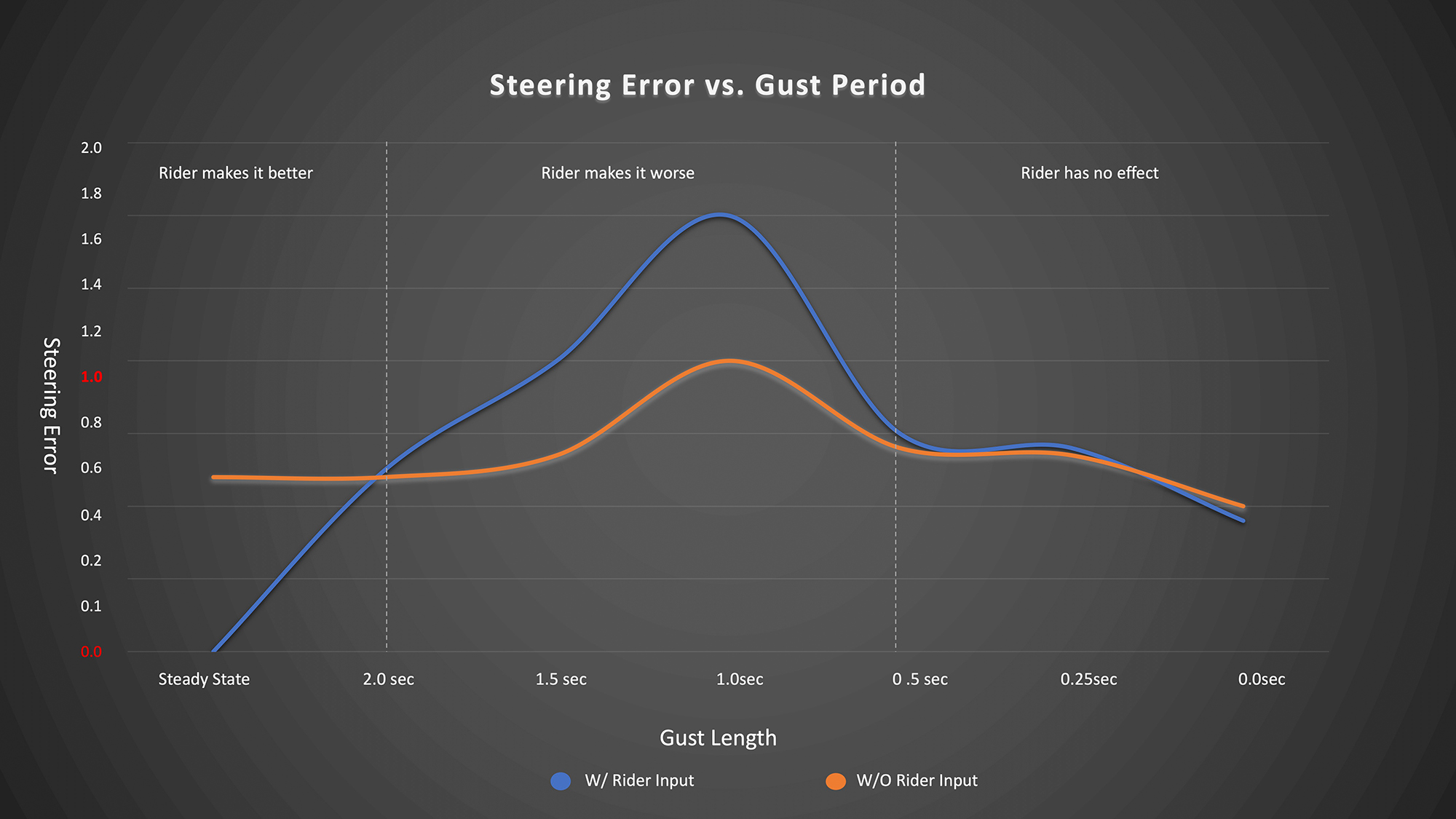

That unusual front shape is all about stability. Roval first started by looking at what happens with a gust of wind and the effect on handling. The findings were that the rider often made things worse. Accounting for rider reaction times allowed the team to create a shape that optimised stability for wind gusts between 0.5 and two seconds. It was that timeframe that studies have shown rider reactions were fast enough to react but too slow to help and so optimising for that time frame makes for a wheel that feels more stable when the rider most needs it. Below that and you can't react, above that and you can react in a helpful way. This isn't new to this generation of wheels but it also didn't lose effectiveness in this generation. It continues to be an important part of the design.

Speaking strictly on the aesthetics front, there are options for satin carbon with either gloss black or gloss white decals. The gloss of the logos sits noticeably raised above the satin of the carbon which almost appears to be raw carbon but is actually a bit smoother. At the front, the peak of the rim is noticeably rounded in the same way that a Hunt 60 Limitless Aero Disc wheel is. As the wheel approaches the tyre there's a large step that Roval says helps keep the air attached with a smaller 26mm tyre.

At the rear, the 5mm narrower rim looks much more oval. In certain lights, the spoke bed looks to be flat with a sharp edge. Trace the shape with your finger though and you won't find anything but a smooth curve both front and rear.

Performance

Pulling the wheels from the box, the experience is on par with other wheels in this class. Wheel bags are more and more of a rarity and there are none included from Roval either. The wheels do come pre-taped and with the tubeless valves installed. You can see in the pictures that I swapped the valve retaining nut, which added a bit of colour but more importantly added an o-ring and space under the nut for the o-ring. In this case, I was just being careful rather than addressing any leaks.

I did not feel the need to swap the valves themselves as there’s no restriction of airflow at the base. Once everything was set, getting the tyres on was the same challenge as is typical. The change Roval made to the overall diameter is actually most important when getting the bead to come loose to remove a tyre. Meaning, get ready to struggle like all tubeless tyre installations. It’s tough to get the bead into the bead channel.

Everything now installed, the very first day out with the Roval Rapide CLX II was what I like to call my after-work time trial. I live near a rails-to-trails bike path that I often ride to the end before turning around. It's a mostly flat 27m / 43km out and back that features perfect pavement and very few people as it quickly leaves the city. It's a route I've done countless times and, despite my best efforts, I tend to always be about the same speed. On that first ride, I set my best time this year.

I'm not going to pretend that's entirely because of a pair of wheels. It's nice for this story but each day I go out there are a hundred different reasons I'm faster or slower on any ride. One thing it does point to though is that the Roval Rapide CLX II is among the fastest wheels I have available to ride. Given the options in my arsenal, that's impressive.

That's not what I think is interesting about these wheels though. What I find far more intriguing is just how comfortable the Roval Rapide wheels are. Roval makes a big deal out of these wheels being fastest with a 26mm tyre so, despite my preference being for a 28mm tyre these days, 26mm is what I spent time testing. Even with a narrower tyre, and the extra pressure that brings along, I immediately pegged these as being the comfortable wheels. So much so that I jumped on a phone call with the engineers behind the design to ask them if I was imagining the effect.

Chris Wehan, Roval Wheel Category Leader, explained to me that the wheel is a system. The rim, the spokes, and the tyres all represent a spring and they all interact with each other. Finding the right feel is all about "years of testing at the highest level." Working hard to get to a point of understanding the band of compliance that works best for a good feeling wheel. Not what people might say they want but what they actually prefer to ride. He was clear that "people think they want stiffer but they actually don't" and Roval worked hard to make sure the whole system of spokes, wheels, and tires works in the way it feels best.

Everyone expects that the Roval Rapide CLX II is a fast wheel. Roval cares deeply about keeping professional riders happy and winning against the best. I don't race though, so I don't care about winning WorldTour races. I want fast wheels you can live with and a comfortable wheel is a fast wheel. These are comfortable wheels.

Verdict

There's nothing I love more than having a deep narrative of intrigue, failure, and ultimately success behind a product. The journey that Roval has gone through to bring the Rapide and Alpinist CLX II to market is a joy to write about. It's just a story though and when you put your hard-earned money down to buy a set of wheels it has to be about more than the story of how they came to market.

Still, there are aspects of the real-world performance of the Roval Rapide CLX II that come into play because of the back story. You can believe the importance of the testing Roval has done, or not, but the fact that it happened has to help you feel a little more comfortable. When you hit a set of railroad tracks at the bottom of a descent and destroy a tyre, which I've done recently, it's nice to know that someone did far worse over and over to the same wheels. It's also nice to know that there's a hooked bead so you can grab whatever tyres happen to be on sale and not worry if they are compatible.

Beyond that though, the wheels have to stand on their own, and against rivals, on the merits of their performance. The wheels you can buy today are now tubeless and that makes them competitive in the current market. They are also very fast wheels with a list of WorldTour wins they can claim. For those not racing there are advantages also. They are some of the most comfortable road wheels I've ever ridden.

The one thing I'd critique is that Roval, and Specialized, have a deep interest in catering to pro riders. Professional riders do amazing things on a bike and they compete in an environment that means every single tiny optimisation matters. But their needs are not always the same as our needs; a 26mm tyre might be technically faster but I'd like to see wheels designed with the needs of everyday riders first. Even though the Roval Rapide CLX II is an exceptionally comfortable wheel, it could be better if the team started with a 28mm tyre.

Tech specs: Roval Rapide CLX II

- Price: €2500 / $2800

- Rim Dimensions: 51mm deep/35mm Wide F: 60mm deep/30mm Wide R: 21mm Int F/R

- Weight: 1505g, 1520g w/ tape and valves

- Hubs: Aeroflange Hubs with DT Swiss EXP Internals and Sinc Ceramic Bearings

- Spokes: DT Swiss Aerolite Spokes 18F/24R

- Tubeless Ready

- 110PSI Max Tubeless with 26mm Tires

- 275lb/125kg Weight Limit

- Handbuilt

Josh hails from the Pacific Northwest of the United States but would prefer riding through the desert than the rain. He will happily talk for hours about the minutiae of cycling tech but also has an understanding that most people just want things to work. He is a road cyclist at heart and doesn't care much if those roads are paved, dirt, or digital. Although he rarely races, if you ask him to ride from sunrise to sunset the answer will be yes. Height: 5'9" Weight: 140 lb. Rides: Salsa Warbird, Cannondale CAAD9, Enve Melee, Look 795 Blade RS, Priority Continuum Onyx