Eurobike 2019: Fizik Adaptive 3D printed saddle launched in conjunction with Carbon

Fizik 3D printed saddle announced as Fizik partner with Silicon Valley based company Carbon

A 3D printed saddle is Fizik's latest innovation in its bid to dominate the components market. The Italian brand's Concepts initiative has partnered with Carbon, a 3D printing specialist based out of California, to launch the all-new saddle at Eurobike 2019.

As Cyclingnews reported recently, Carbon has also helped Specialized create a 3D printed saddle, yet Fizik claims to be a step ahead in getting the product to market, hinting at availability before the end of the year.

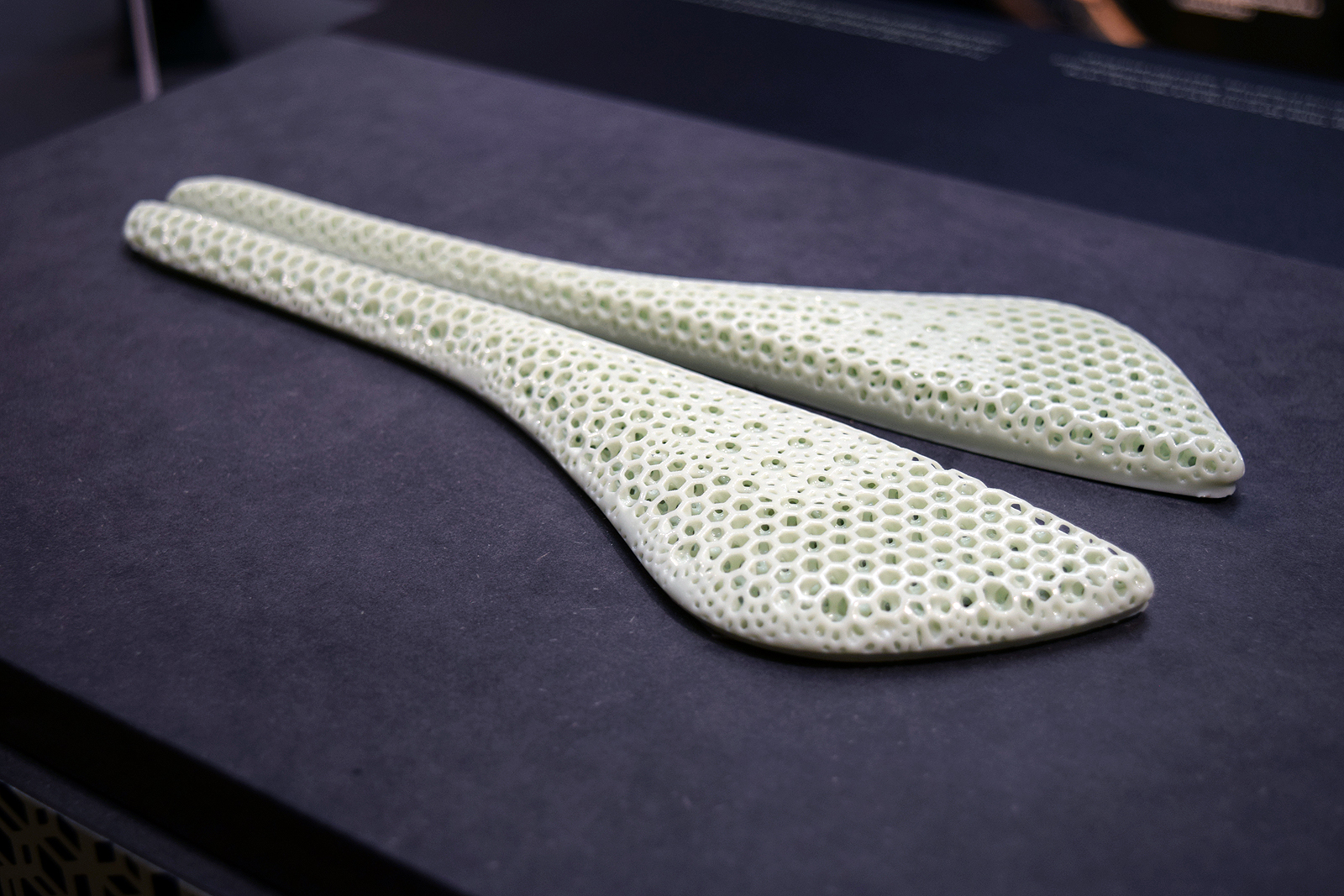

The Fizik version uses the same revolutionary Digital Light Synthesis (DLS) printing method to create the polymer lattice padding. The printing method uses “digital ultraviolet light projection, oxygen-permeable optics, and programmable liquid resins to produce parts with excellent mechanical properties, resolution and surface finish.” Which all sounds very exciting.

"We’re proud to partner with Fizik to unlock their unique product vision to push the limits of saddle design," says Erika Berg, Head of Application Development at Carbon. "Fizik used the Carbon Lattice Engine to match optimised response profiles based on rider feedback and create a digitally tuned lattice geometry for the Adaptive - enabling differentiation based on their unique product vision and design."

The result is a saddle which Fizik claims to improve comfort, support and power transfer. To do this, Fizik has been busy collecting pressure mapping data over the last nine years which has allowed Fizik’s designers, sports scientists and engineers to identify key areas for attention on a saddle. With the ability to manipulate the lattice and material Fizik can create seamless zonal areas with specific engineered properties.

Previous methods of manufacturing were always limited by the densities of foam that were available and the methods in which they were bonded together. However, the use of 3D printing should offer much greater control over the density, dampening and elasticity the material as well as the transitions between them. Individually tailoring saddles to a rider based on their biodynamic and biometric data could potentially have a significant effect on how bikes are fitted in the future.

The first Adaptive saddle will be based on Fizik's Versus Evo 00 platform - a carbon fibre performance saddle, that uses a full-channel design and delivers power transfer in a featherweight package. Using an already proven high modulus carbon body and rails as a base to which the new 3D printed padding will be attached. Although Fizik has currently only announced a single Adaptive saddle model, the Italian brand has expressed plans to bring Carbon’s EPU 41 material and technology to a range of different models.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

The long-term possibilities of this 3D printed technology are what excites Cyclingnews; eventually, an in-store system could collect consumers' pressure-mapping, this data can then be fed back to the 3D printers at the Fizik factory before a completed unit is shipped direct-to-consumer.

This new technology creates all sorts of possibilities, as Luca Mathia Bertoncello, Fizik Brand Director, explains: “Digital Light Synthesis unlocks a new era in saddle design and manufacturing, driven by athlete data and agile manufacturing processes. It means we can fully release our creativity – transforming not just what we make, but how we make it, bringing a whole new way of thinking to cycling saddles. Our aim is to provide riders with bespoke performance products tailored to their individual biodynamic data.”

The saddle will come in two lengths (139mm and 149mm) and will be available over the coming months at Fizik.com as well as in selected retailers.

There are still many questions surrounding this product; the material's durability, returns policies, how it actually relates to comfort on the bike, and of course, cost. We're also wondering if Carbon has any other cycling-tech collaborations up its sleeve, so stay tuned as Cyclingnews will be sure to follow this story with a keen eye.

Cyclingnews is the world's leader in English-language coverage of professional cycling. Started in 1995 by University of Newcastle professor Bill Mitchell, the site was one of the first to provide breaking news and results over the internet in English. The site was purchased by Knapp Communications in 1999, and owner Gerard Knapp built it into the definitive voice of pro cycling. Since then, major publishing house Future PLC has owned the site and expanded it to include top features, news, results, photos and tech reporting. The site continues to be the most comprehensive and authoritative English voice in professional cycling.