Trek rolls out new weapons for Discovery Tour campaign

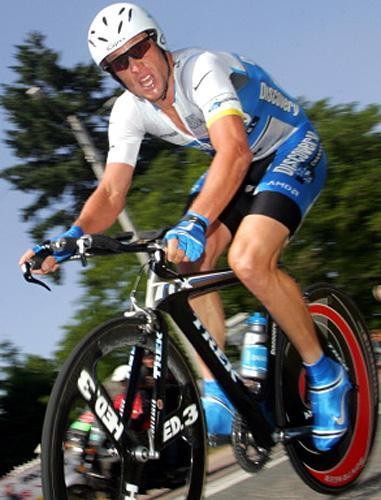

Lance Armstrong and Discovery Channel have new bikes for the time trials and the mountains in the...

Tech feature - June 16, 2005

Lance Armstrong and Discovery Channel have new bikes for the time trials and the mountains in the Tour de France. Tim Maloney takes a look.

The Tour de France isn't necessarily won in the time trials - analysis of his six Tour wins shows Lance Armstrong picks up time on his rivals in the mountains too - but it can surely be lost in them. Armstrong's Discovery Channel team has never taken any chances with Tour time trials, and this year the team's bike supplier Trek has built new bikes for the team's efforts against the clock.

Trek's new TTX time trial bike has already seen action in the Critérium du Dauphiné Libéré in Aix-les-Bains. Team leader Lance Armstrong was fifth in the prologue, and then third in stage three's hilly 46.5km ITT in Roanne. However, even Trek concedes that the new frame is an incremental improvement and not a major leap in performance. Trek's pro team liaison Scott Daubert told Cyclingnews, "UCI regulations on bike design limit the design parameters Trek can work with, plus the human body can only do so much work over a set time or distance, so at this point we have nearly maxed out the efficiency of our design."

"Our present TT frame was born after the 1999 Tour from much study and testing and as we have recently tried to bring it to the next level, surprisingly it's been very hard to make this present TT frame even faster," said Daubert. He added Trek's testing showed the previous frame was similar in performance to rival designs such as the Cervelo P3 Carbon used by Ivan Basso and CSC and the Walser time trial bikes that are often seen under other maker's decals - as long as there was no wind. "Our design is more efficient in cross-winds," said Daubert.

With this data at hand, Trek engineers then redesigned the head tube, top tube and down tube shapes to make the old TTT frame an even more efficient bike, with the help of a Computed Fluid Dynamics (CFD) design program. Daubert explained, "This software can evaluate shapes in given mediums (air, in our case). Our Trek engineers input the shape and wind speeds and CFD calculates where the problems are. As far as we know, Trek is the first bike company to use CFD software to design a complete bike as we have with the new TTX."

Once Trek created the first TTX prototype in its Waterloo, Wisconsin facility, Lance Armstrong then tested the bike during a training ride in Girona, Spain, where it gained the Tour champ's seal of approval before being raced. Details of the new Trek TTX include a one-piece head tube/top tube derived from the Madone frame that is uniquely shaped to make the front of the TTX more rigid when accelerating or climbing out of the saddle; and a deep cross section down tube that creates lift in cross winds yet is aero in head-on winds and presents a smaller frontal area with less drag.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Trek has further refined the down tube on the TTX via an improved aero shape that's more like a double sided axe than an airfoil. Trek says this aids airflow bridge from the front wheel on the down tube. Steering is via a narrow cross section Bontrager TT Aero fork, with a new specific fork leg cant that reduces low pressure that previously built up behind the fork legs and created drag. Up top, an all new design one-piece Bontrager Aero bar was used at the Dauphine Libere. This is and is built in OCLV Carbon fibre for light weight and super stiffness and the design eliminates drag caused by excess seams and joints.

But the TTX isn't the only new two wheel weapon Armstrong will have in his quiver when he lines up in his quest for a seventh consecutive Tour de France win on July 2. Trek has taken last year's Madone SSL and refined it to better suit Armstrong's demands for a lightweight, stiff climbing bike. Lance's new 2006 Trek Madone SSLX started out as a production OCLV 55 Carbon Madone SSL, already the lightest road bike Trek has ever made. Trek engineers were certainly chanting Lance's personal mantra - "lighter and stiffer" - as they looked at how to improve the SSL.

Trek's solution was to formulate a new carbon fibre mix called OCLV Boron. With boron added to the OCLV carbon fibre composite, the frame gained a 15 percent increase in rigidity. The boron was only used in a special lay-up of add-in directional composite strips made of carbon fiber and boron at the bottom bracket. Daubert explained that "OCLV Boron is very strong under compressive loads, so when the layers of our OCLV carbon fiber are laid up, a layer of boron can be sandwiched between the layers. By strategically adding a very small amount of boron in compressive load areas, we can use less carbon and make a stronger and lighter frame and/or component." Daubert also pointed out that Trek has added OCLV boron to the all new Bontrager Race XXX Lite VR handlebar. According to Daubert, these new Bontrager 185 gram bars are as light as any bars available, yet test stronger due to the inherent strength of the OCLV Carbon.

"Included in the OCLV Carbon mix used in the Bontrager Race XXX Lite VR handlebar is is OCLV 110 in the remainder of the main bar and our lightest carbon ever used, OCLV 55 in the drops," said Daubert. "Key to the weight savings and strength is the use of OCLV Boron in the stem clamping area and the underside of the bar, where the main compressive loads are. Just like Lance's new Trek Madone SSLX frame, each handlebar is hand-laid in our proprietary OCLV molds. This technique allows the careful and strategic placement of a mix of OCLV carbon to attain the sought-after weight and performance that are required for Lance to choose them."

Daubert believes that one vitally important aspect of Trek's close involvement with the Discovery Channel team is that the company makes the team's bikes and other equipment in its own factory. "Trek has been making OCLV carbon fibre frames since 1992," he said. "Each component is designed, tested and handmade at our factory. And none of this innovation would be possible if each OCLV frame, handlebar, wheel and seat post made didn't rely on our proprietary OCLV Carbon technology. From beginning to end, we control the process, right here in our factory in Waterloo, Wisconsin."