SRAM Red makes an appearance at Tour de France

This year marks the Tour de France debut of SRAM's Force group and time trial-specific components on...

Tech Feature: SRAM Red, July 11, 2007

This year marks the Tour de France debut of SRAM's Force group and time trial-specific components on the bikes of David Millar, Iban Mayo, and the rest of the Saunier Duval-Prodir team. This is significant in its own right not only given the nascent status of the group, but also of the company itself: SRAM has only been around for twenty years (and has only offered road-compatible components for a fraction of that) yet is already trying to play with the big boys in the sport's greatest arena.

SRAM borrowed some of its own TdF spotlight by also choosing to show off samples of its new Red group, a premium sub-2kg (claimed) offering that slots in above Force and Shimano Dura-Ace, but just shy of Campagnolo Record (at least when looking at it from the perspective of the currently ultra-valuable US 'peso'). The existence of Red is hardly a secret at this point in time, but physical sightings were limited to test mule prototypes until now.

By far the biggest surprise was the Red cassette. Contrary to earlier information, there is not a scrap of titanium or carbon fiber to be found; rather, it is machined almost entirely of steel. Yup, you heard correctly, good old iron-and-carbon-plus-a-few-bits-of-other-stuff steel, but SRAM looks to have taken advantage of the material's superb durability and rigidity without keeping its usual portly weight.

The new cassette is perhaps best described as an empty shell, instead of a series of flat gears stacked on top of each other. SRAM starts with solid steel billet and then proceeds to CNC machine out the entire interior and backside of the cassette, leaving just the exterior shape behind (which naturally incorporates its OpenGlide tooth profiling). This not only makes it light, but should also make it exceptionally rigid. Rider torque (in nearly any gear) is transferred to the freehub body via a relatively thick splined aluminum plate that is pressed in to the back of the structure. The smallest cogs are still individual bits that will stack on top, followed by a conventional lockring.

The prototype we saw used a solid aluminum plate, but it's easy to imagine that it might gain a few lightening holes by the time it hits production (and if not, we're sure someone will add a few). According to SRAM, the plate will be thick enough to prevent galling on softer non-ferrous freehub bodies but we'll have to wait and see. Either way, we can't argue with the bit's staggering weight: the prototype was just 100g, minus the smallest three cogs and lockring.

Otherwise, much of what was leaked earlier has turned out to be true and SRAM seems to have directly addressed virtually every complaint we had with Force (and there weren't many). The new DoubleTap levers will boast substantially reduced shift lever throw courtesy of SRAM's Zero Loss technology adapted from its mountain bike division. This will obviously speed up the already-snappy rear shifts, but will be most noticeable up front. It has also been confirmed that the trim position for the front shifter has been moved to the large chainring. "Cross-chain to your heart's delight," said SRAM Road PR Manager Michael Zellman.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Lever ergonomics on Force were already quite good, but Red promises to be even better. The shape of the now-carbon shift paddle has been revised for easier access from the drops, and the brake lever blade has grown in length by about 10mm, bringing it more in line with its competition. Both the brake lever blade and shift paddle will also be independently adjustable for reach (and why hasn't someone done this before?).

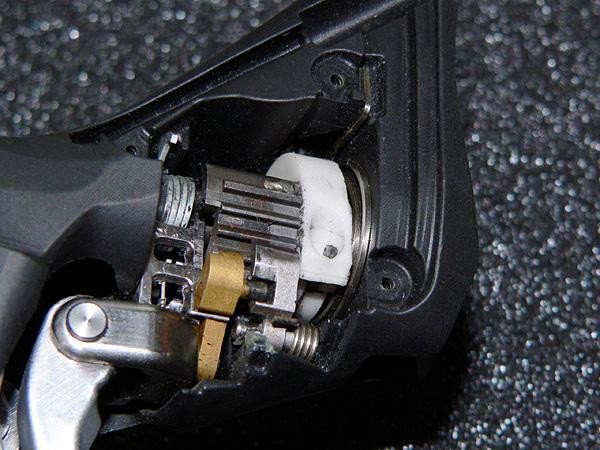

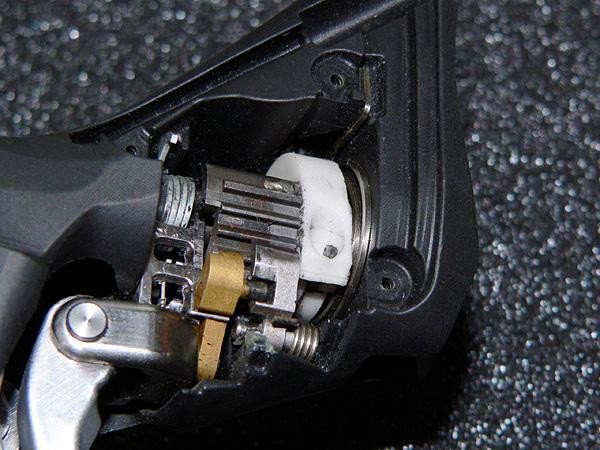

SRAM has revised the lever body itself a bit as well, while a change to lighter-weight carbon-filled nylon instead of glass-filled nylon shaves some weight along with the newly hollowed-out exterior. We also confirmed that users will finally be able to route the derailleur housing either in front of or behind the handlebars according to their preferences (which also means that we can put an end to taking a Dremel tool to test bikes…). Weight on the single rear shifter was just about 120g.

Changes to the front and rear derailleurs are about what we expected, with the former now equipped with a titanium cage and the latter boasting a full carbon fiber pulley cage, a magnesium outer parallelogram plate, titanium main spring, and ceramic bearing-equipped pulleys. As compared to Force, the prototype Red rear derailleur was marginally lighter at about 150g; unfortunately, the front derailleur was still too far away from production versions to provide any valuable insight into weight savings but the titanium cage will surely shed some significant grams.

SRAM didn't show us the complete crankset or brake calipers yet, but the large chainring will be built with a solid outer wall and relieved backside a la Dura-Ace and we've already confirmed that the new calipers are still aluminum but equipped with an array of lightening windows (including on the brake pad holders).

Based on the appearance of the prototype samples we saw, it was obvious that they were built on production (or nearly production) tooling rather than formed layer-by-layer via SLA. Indeed, SRAM confirmed that it had already completed pilot runs and says full production product will begin shipping to OEM suppliers and aftermarket channels on October 1. We obviously still can't report on any firsthand experience of the stuff in use, but SRAM has continued to hold our interest with its endless stream of teasers and we'll report on the performance of test samples as soon as possible.