Road bike hubs: Pawl vs ratchet

Road bike hubs are central to the performance of your wheels, but which type is better?

As cyclists, we obsess about the rims of our road bike wheels; their weight, their aerodynamic properties and stiffness, not to mention the ever-present debate around tubeless technology, but we often ignore our road bike hubs, despite it being central to performance.

With its mechanical components hidden in a shell, the hub is underappreciated – until it goes wrong, and you are stranded at the roadside or your bike becomes a fixie.

The freehub that engages chain-driven input to your rear wheel, is a design balancing mechanical accuracy and durability. Of all the road bike hubs available, two freehub configurations dominate: Pawl and ratchet.

But how do they differ and is one better than the other?

- Best road bike wheels: Our pick of the best wheelset upgrades

- Best lightweight wheels: Shallow wheels for climbing and accelerating fast

- Best gravel wheels: Our pick of the best gravel bike wheels for racing and adventure riding

What is a pawl hub?

Road bike hubs that use this drive system rely on a selection of pawls that engage a drive ring surrounding them inside the freehub.

The pawls (of which there are usually three or six positioned) are spread evenly through the hub's 360 degrees. They are positioned at an angle, on a pivot, with teeth at the exterior end. Each pawl is supported by a leaf spring which pushes it outward, forcing it to mesh with the drive ring.

The drive ring also features teeth throughout the circumference of its inner face, and it is the meshing of the teeth on both components that creates the engagement.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

When pedalling, the freehub is rotated in a direction that counteracts the angle of the pawls, which when combined with the friction in the meshing of the teeth, forces the pawls to pivot outward, which further enhances the engagement, effectively locking the two components together. The result is that your pedalling input applies forward drive to the rear wheel.

When freewheeling - not pedalling and allowing the bike to roll freely - the wheel is rotating in the same direction as the angle of the pawls, which causes them to pivot inwards. The spring still tries to push the pawl outwards causing the pawls to skip across the teeth on the drive ring. This is what causes the ticking sound, and gives each freehub design its characteristic sound.

With a pawl system, it's possible to increase the engagement to extremely small angles - with Industry-9 leading the charge with its Hydra hub that engages as quickly as every 0.52 degrees.

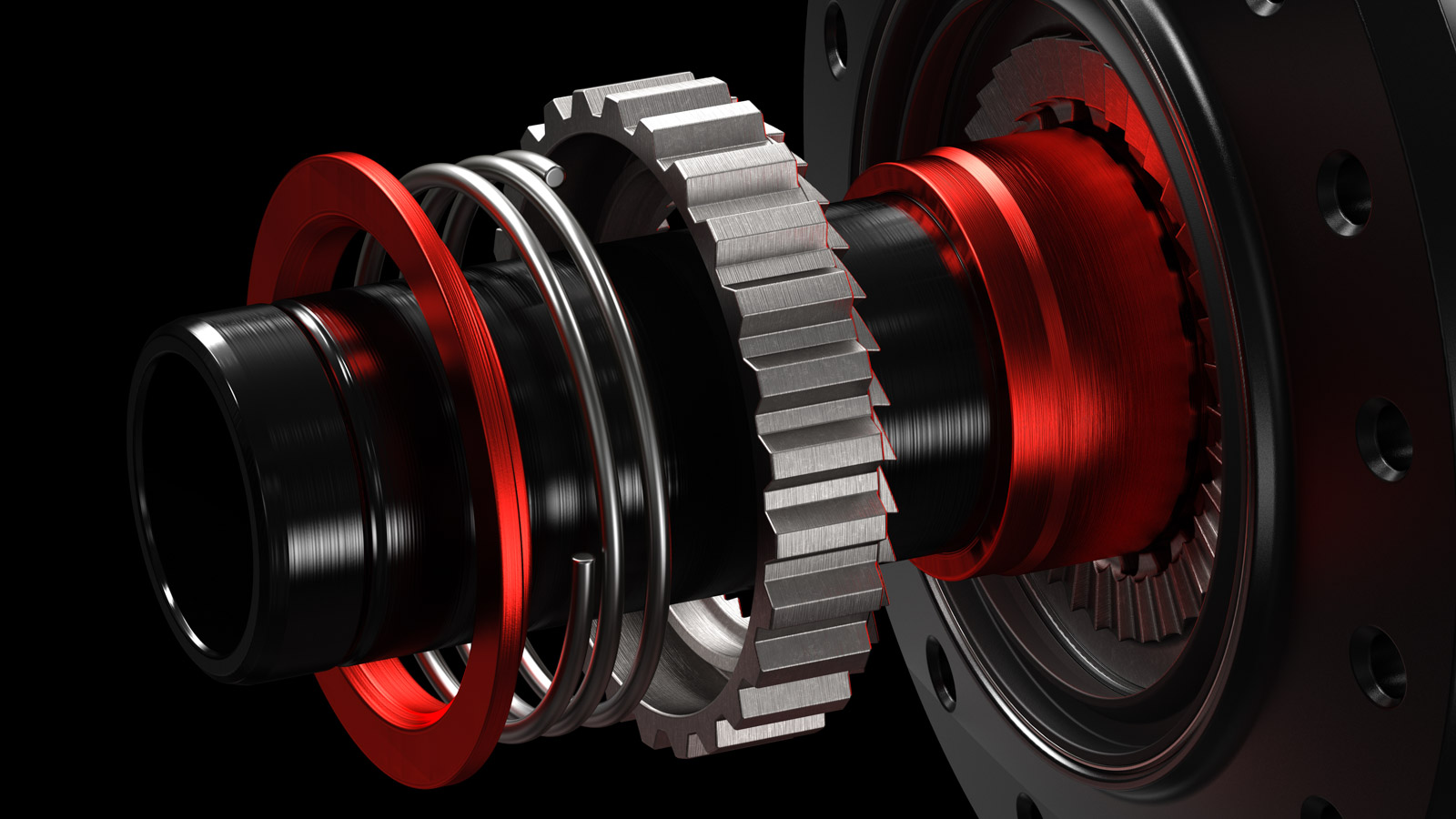

What is a ratchet type hub

Popularized by DT Swiss, the ratchet drive is also spring-loaded, but it doesn’t use pawls. Instead of three or six pawls pivoting out and interacting with a surrounding drive ring, a ratchet drive uses two toothed rings, placed next to each other on a horizontal plane.

The engagement works in a similar way, in that the teeth on both rings engage and lock together, but are angled in such a way that they engage in one direction, but slide past each other in the other, and a spring helps to ensure they remain in contact. This has a lot more mechanical contact, using all its available teeth at all times.

In the DT Swiss star ratchet design, you have all its teeth as a single metal component, making the possibility of mismatched engagement nearly impossible. With a single spring and all those star ratchet teeth engaging, instead of six individually sprung pawls, there's a lot less to go wrong.

The most used star ratchet configurations feature 18-, 24-, 36- or 54-teeth. With the higher tooth-count engaging more quickly. However, there's a limit to how many teeth you can add without reducing their durability and for this reason, star ratchet systems struggle to reach the same number of engagement points as pawls systems.

Durability and maintenance

Although road cyclists will rarely apply the kind of leverage that mountain bikers do in a very low gear, the pawl hub design can suffer faulty engagement.

In very specific conditions (surface friction, rider input, gearing), the pawls can miss their initial engagement point into the drive ring. That can mean a delay between pedal input and rear-wheel response, which is a lot more pronounced in the low gear riding that mountain bikers do – but can become equally annoying on a road ride.

Another issue, with the potential for mechanical wear, is having the pawl only partially engage with the drive ring’s matching teeth. When pawls don’t perfectly engage as designed, they can trigger wear on the freehub.

Hubs work hard for a living and require maintenance. Your rear hub needs cleaning and lubrication, but with the pawls being under such significant spring tension, you need to be meticulous and careful during disassembly.

Many an inattentive home mechanic has experienced the surprise, followed by great frustration, of having hub bits projected all around the garage when attempting a DIY service.

If they have the potential for fiddly engagement and are harder to service, why are so many rear hubs engaged with pawls? For the most part, they do work well, especially when packaged in a hub shell by skilled industrial designers.

The legacy of pawl hubs, supported by a list of proven component suppliers, has given this hub design the scale to become successful.

Simplicity and ease of serviceability are two meaningful advantages of the star ratchet system. A long period of patent privilege kept many hub brands from licensing the ratchet, leaving DT Swiss to court riders who believed in the star ratchet concept.

Although there is now greater freedom for more brands who would like to use a ratchet design, the cost and complexity of redesigning their product portfolios, have prevented this.

Which one is best for you?

Road bike hubs should be light and produce as little friction as possible. This differs from what mountain bikers require, where immediate engagement is the most important factor.

Road cyclists desire a hub that spins most freely, and rapid engagement is an acceptable sacrifice for this. When you add pawls, or more teeth to a ratchet/drive ring, mechanical drag can increase. Though it must be said, that the drag effect is marginal.

Rear hubs live a more charmed life on road bikes, as opposed to those being used in mountain bikes. The swiftness of engagement might not make much difference for real-world riding, but a hub failure is terminal, for any ride. If you like the idea of home maintenance, a star ratchet system is easier to keep in working order.

For those wanting rapid engagement, pawl systems are currently still the way to go.

Lance Branquinho is a Namibian born media professional, with 15-years of experience in technology and engineering journalism covering anything with wheels. Being from Namibia, he knows a good gravel road when he sees one, and he has raced some of Africa’s best-known mountain bike stage races, such as Wines2Wales and Berg&Bush.