Olympic medals, rainbow jerseys and a 104-tooth chainring: Inside the engineering legend of Royce

British brand Royce has been responsible for some of the finest hubs, bottom brackets and components of the last 40 years

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Cliff Polton, engineer and owner of Royce UK, is still waiting for the spoke nipples he ordered from Italy nearly a quarter of a century ago to arrive. Tasked with building the wheels for Chris Boardman's Athlete’s Hour Record attempt, he finally gave up waiting and made the special spoke nipples himself.

“We’re engineers, we just made them,” Polton, a lifelong engineer who turns 80 this year, explains from his small business premises on the edge of the New Forest, Hampshire, England.

Royce is a small British engineering company, founded in 1980, that has produced arguably some of the most admired and highest-quality bicycle components of the last 40 years. Royce's marketing has always been minimal, there’s no social media, and you will need to pick the phone up to make an order, but a reputation grew, and the firm's simple yet elegant silver hubs and bottom brackets in particular have long been regarded with reverence.

Polton’s passion for his work is immediately evident. This same passion extends to pedal car racing, a branch of the cycling tree in which Royce teams enjoy a lot of success. Polton, who still competes regularly himself, proudly shows several large trophies in the workshop, as well as his custom-made four-wheel pedal cars themselves.

The priority at Royce is quality engineering. In today’s market, Royce is one of the last remaining bastions of small-scale, British engineering firms making parts for the bicycle.

A commitment to quality

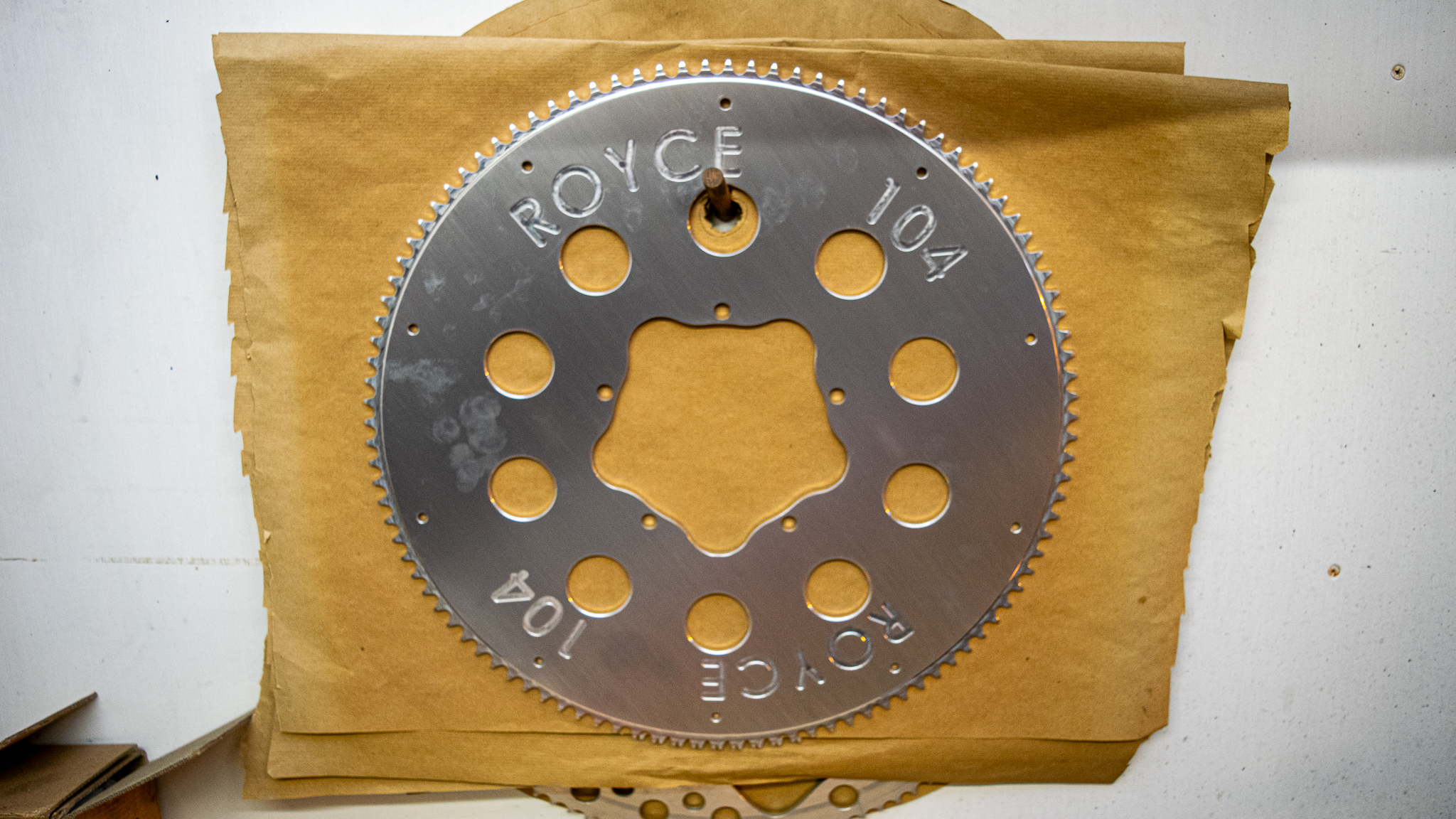

Royce bottom brackets and hubs have become the company's calling cards. Over the years, however, cranksets, chainrings, seatpost clamps, sprockets and quick-release levers have all been produced as well as various custom jobs, like some huge 100+ teeth chainrings for various land speed record projects. The company's day-to-day business extends far beyond the cycling world though, Polton explains that among other things, he is currently working on a job for the Ministry of Defence.

Royce even manufactured two beautiful-looking derailleurs in 1980 that were inspired by Campagnolo equipment of the time but designed to perform even better. The derailleurs never made full production, now lost, no one knows where the missing pair currently are. A framed photograph in a hallway is the only evidence of their existence.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Polton explains there are no tricks in engineering and sums up the secret to Royce's success and longevity with an engineer's pragmatism:

"We use the best materials we can for the job, the tolerances are tighter than other people's, and we use the best bearings we can."

Alongside the quality materials, and very tight tolerances. Royce hubs, in particular, which use titanium hub axles, are polished until they shine. The simple 'R'' logo on each hub shell doesn't need to shout.

Royce orders are assembled or manufactured to order, so there are plenty of individual components neatly stacked in parts bins in the upstairs assembly area, but not many complete hubsets lying around. A drawer full of beautifully machined titanium hub axles evidences this.

Royce's range toppers are the Racing Gold hubs, which carry a £1,200 price tag. The hub shells are machined from titanium, then titanium nitride coated (a special coating that can reduce friction), and then highly polished.

Royce uses NTN bearings exclusively and their exacting close manufacturing tolerances mean that bearings will last a long time. Bearings are one thing Royce doesn't produce.

"We couldn't manufacture bearings. Millions of pounds go into making machinery to make bearings, so we buy the best bearings we can."

Polton admitted to becoming disenchanted with some bicycle component designs over the last decade or so, believing many modern hub or bottom bracket designs don't improve on what has gone before. This extends to the buzz around ceramic bearings.

"At over 20,000 RPM, ceramic bearings are great. Now, cyclists aren't revving over 20,000 RPM. Buy good bearings with proper seals if you want to keep them clean. Why spend 100-odd quid for a bearing, when you can buy one for £8, you're gaining nothing, maybe a couple of grams.

"I would rather sell a bottom bracket to somebody. Sell one of our axles to somebody, and know that in five years, it will still be running smooth. I don't want to have to replace bearings after six months."

Though it hasn't been widely adopted, Polton is proud of the tri-lobe bottom bracket axle standard, which uses the same taper angle as a regular - and far more common - square taper design but is stronger and provides a stiffer platform thanks to the ability to use more material. Polton explained the inspiration came from a part on a German tank that used a similar design philosophy.

Ridden and raced by the best

Over the years, plenty of the sports champions have used Royce equipment, and the brand became the go-to name for bottom brackets and drivetrain components from the '80s into the 2000s.

Despite this, the company hasn't felt the need or desire to embrace modern standards and doesn't sell as many hubs or bottom brackets now. Royce's zenith was probably in the era of square taper bottom brackets and non-disc hubs.

Royce worked with world and Olympic road race champion Nicole Cooke in the earlier part of her career, producing special bottom brackets and even bottom bracket shells for the Welsh rider. She stays in touch all these years later.

Sean Yates used Royce's bottom brackets in his bikes for certain races too, time trials in particular, and explained Royce was almost taking care of marginal gains for riders long before 'marginal gains' was a thing.

"Nowadays there are 101 different types of bottom brackets," Yates told Cyclingnews. "Twenty-odd years ago, to my knowledge, there weren't many companies doing real bespoke products for racing.

"I wanted to have the best equipment available. Being a British company, it was always good to support the homegrown talent, they were really trying to develop a product that was top-level. It's a labour of love and they [Royce] take real pride in their product."

Phillipa York is another rider who says Royce was the brand to use for big races and echoed Yate's views on upgraded parts being the attraction.

"At the time, Royce produced top-quality parts that were lighter than the mainstream offerings. They had titanium upgrades for bottom brackets which I used in my race bikes whenever possible and their hubs went into the wheels Pete Matthews [a British wheel builder] built for me when it was mountains or championships."

Royce also had an interest in mountain bike components in the mid to late '90s, a key time in the growth of the sport which is a lot younger than road racing.

Royce had a few domestic race teams in the UK which it sponsored and provided parts for, with household name pro-riders like Steve Peat and Rob Warner among its users.

Jam Price, a British-based racer and mechanic raced for the teams and remembers the time fondly.

"It was laid back, always supportive, without pressure to get results as long as we enjoyed it and represented Royce in the right way.

"I always felt Cliff treated me like a son, he was always there for a chat as well as the bike stuff."

There is a distinct lack of fanfare or self-promotion regarding Royce's history. The company has a storied past that you feel some brands would dine out on time and again. Polton values relationships, friendships and helping fellow cyclists do their thing over any personal accolades and admits he has forgotten plenty of the old stories.

The company produced the hubs, spoke nipples and other parts for Chris Boardman's Hour Record wheels, providing three sets in total as spares were needed. What's interesting here is that Boardman rode with a power meter even then, and used the Mavic Comete disc and iO five-spoke combo in races. He would have known the wattage difference between a disc and five-spoke and the traditional wheels the record rules demanded, Royce was the answer when it came to saving some watts.

History aside, Royce components are still being ridden at the highest level even today. Team GB approached Royce and Polton for drivetrain ideas ahead of the 2021 Olympic Games.

As we talk, Polton produces a soft drawstring bag, inside of which is a beautiful, shining gold track sprocket. It was produced, he says, for the Great Britain Cycling team for the Olympic Games in 2021. Study photos from Paris 2024, and the sprockets being used look very similar.

"It's made of titanium," he began. "It's then titanium nitride coated, which is three times harder than carbide, so it's got a very slippery surface. The pitch is three-eighths of an inch, instead of half an inch. It uses a roller-type chain, which enables the chain to pass over more freely."

A framed rainbow jersey also hangs proudly on display on the workshop stairs, it was won by Paris Paralympic Individual Pursuit champion and multiple world track champion Jozef Metelka who uses Royce equipment on his track bikes. Polton pulls open a box and reveals a ceremonial Kimono awarded to winners at the 2021 Tokyo games, Metelka delivered it personally and the two friends then went for a pint.

The fire burns on

There may well be less than a handful of manufacturers producing bicycle hubs in Britain now. There is Royce of course and Hope components are always popular, but beyond that, there isn't much to choose from these days.

After 40 years, the fire seems to burn as bright as ever for Polton and he answers without hesitation at the mention of retirement.

"I'm not retiring. No."

He also explains he has no plans to stop racing pedal cars anytime soon, another great passion.

"I love my racing. I love racing with my daughter. I do the pedalling as well. Pedal car racing is absolutely great."

Decades of effort have gone into Polton's work, and his efforts over the years have earned respect and friendship.

"I've done everything I want to do, really. I earn friends, they come and see me. We go out for a pint and fish and chips. I couldn't ask for more really."

Polton is surely aware of both his and Royce's legacy and the cyclists who have come to admire his components over the years. He freely admits to not being a marketing man, engineering excellence was - and is - his only concern.

"I like sorting out problems with jobs, not sorting out petty things that don't really matter to me. Everything can be made better. All I want to do is do a good job. If I can improve the efficiency of something, I'm satisfied."

Tom joined the Cyclingnews team in late 2022 as a tech writer. Despite having a degree in English Literature he has spent his entire working life in the cycling industry in one form or another. He has over 10 years of experience as a qualified mechanic, with the last five years before joining Cyclingnews being spent running an independent workshop. This means he is just as happy tinkering away in the garage as he is out on the road bike, and he isn’t afraid to pull a bike apart or get hands-on with it when testing to really see what it’s made of.

He has ridden and raced bikes from an early age up to a national level on the road and track, and has ridden and competed in most disciplines. He has a keen eye for pro-team tech and enjoys spotting new or interesting components in the wild. During his time at Cyclingnews, Tom has already interviewed some of the sport's biggest names including Mathieu van der Poel, Tadej Pogačar and Alberto Contador. He's also covered various launches from brands such as Pinarello, Ridley, Specialized and more, tackled the Roubaix Challenge sportive aboard his own rim-brake Cannondale SuperSix Evo, tested over 20 aero helmets in the wind tunnel, and has created helpful in-depth buying advice relating to countless categories from torque wrenches to winter clothing.