How accurate is a well used torque wrench? We went to a lab to find out

We took three well-used torque wrenches to get calibrated to see if they really were still accurate

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Over the course of this year I've spent some time exploring the subject of torque and torque wrenches. I worked on and overhauled our best bike torque wrenches buyers guide earlier in the year. My research on this and my interest in the topic generally led to the creation of a few pieces of work on the subject.

I did some research and spoke to aircraft, bike and automotive mechanics from other industries, comparing their experience and use of torque compared to the bike industry. Comparing knowledge from mechanics in different industries provided some useful insights and comparisons as well as some tips to take away and possibly implement when working with bikes. I also spoke to several large tool manufacturers to get some tips and best practice advice straight from the top on using torque with bike fasteners and how to best care for your own tools and torque wrenches.

This final torque piece follows up on a point that has been mentioned several times in these pieces and that was repeated by both manufacturers and mechanics alike. This was to ensure that torque wrenches are regularly calibrated to ensure accuracy can be ensured long term. Most manufacturers recommend and can provide yearly calibrations around every 50,000 clicks (uses), or every 12 months, whichever comes first. A torque wrench that has been in use for years, used as an emergency breaker bar, dropped, or left set etc may not be working accurately any more which means potentially over or under-tightened bolts and inaccurate or even unsafe work.

Instead of speculating, we found some battle-weary torque wrenches and booked them in for calibration testing. The visit was really interesting, I learnt an awful lot and it threw up some really useful points if you own or work with bikes and torque wrenches.

Several of the representatives we spoke to from tool manufacturers cited a potential need for increased awareness in the bike industry when it comes to re-calibrating torque tools to ensure accuracy. I've also never personally sent a torque wrench for calibration or heard of a shop doing it in my years working as a mechanic, and most mechanics I spoke with said they hadn't usually bothered. Some mechanics I asked during my research even said they just brought new torque wrenches every few years.

The torque wrenches in our buyer's guide were all brand-new units and all good-quality ones. Though I had worked through a range of service jobs on them all during testing they were brand-new units and I expected would only tell us what we knew already if we took them for testing.

For a more interesting set of results and piece in general I needed some used and older wrenches. I had my own Proxxon torque wrench to use, which had done a few years of heavy work and even sustained a couple of drops. The other two wrenches came from the mechanics at my old workplace Gorilla Coffee Workshop. Mechanics Paul and Josh were interested and on board with the project straight away and provided a couple of their own torque wrenches for calibration.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

The torque wrenches we sent for calibration were all click-style and as I've mentioned in the past, I think this style tends to be the most commonly seen in the bike world.

To recap and to help you picture what's going on inside your torque wrench in the context of testing, I will use Effetto Mariposa founder Alberto De Gioannini's clear-cut explanation of how a click-style torque wrench functions:

"It's a simple but precise mechanism, based on a calibrated spring that is put under a certain load when setting the "torque" dial. The spring is compressing a bearing placed under the wrench head. When the torque applied to the bolt reaches the torque value set in the tool, the bearing allows the head to move and "click"." he explained.

I headed to the Calibration Select Metrology lab in Smethwick, Birmingham. The Metrology Services division is an arm of the long-running company Avery Weigh-Tronix which has been servicing and maintaining weighing equipment for over 200 years.

Avery Weigh-Tronix offers a range of metrology services - metrology being the science of measurement. The Calibration Select service and lab are set up to provide calibration and testing services for torque, dimensional, pressure, and electrical equipment amongst others. The lab is also UKAS accredited to the most up-to-date ISO 17025:2017 standard (ISO is the International Organization for Standardization). UKAS is a UK government-appointed body that accredits organisations providing services across a variety of sectors including calibration testing. For reference, our calibrations cost around £40 per torque wrench though prices vary depending on the job.

Yousuf Ahmed, the lab team leader, carried out the calibration testing on our torque wrenches and gave me a tour of the lab and the various different metrology testing bays, from dimensional to torque. It would have been too easy to pick his brains all day but we had some torque wrenches to test. The lab was spotlessly clean and temperature controlled (a must for UKAS accreditation) with temperature sensors dotted around to ensure controlled testing conditions.

Yousuf explained the need for "a never-ending trail of accountability and traceability" when it comes to metrology and the sort of testing the lab carries out. Years of test results are logged and a point I hadn't considered was what calibrates the calibration machines, and how far that process can go in the search for ultimate accuracy. You start to go down the rabbit hole here, and the processes in place could almost be never-ending. But quarterly verification checks to calibration equipment take place, as well as yearly calibration being carried out to ensure nothing is thrown out or inaccurate, thus guaranteeing the equipment doing the calibrations is accurately calibrated too. I didn't know what to expect from a Calibration, I didn't know what equipment Yousuf would use to check the wrenches if he'd open them up to work on them or use some sort of rig to check them. I learnt the lab calibrate torque wrenches to two ISO standards. One being ISO 6789:2003 and the other being the newer ISO 6789:2017 standard, both up to 2,500Nm.

Our wrenches would be calibrated to the 2003 ISO standard which involves a simpler test and can offer a faster tool turnaround time for businesses. Although classed as ‘withdrawn’ the 2003 standard testing is still very much used and widely available. Yousuf explained torque wrenches manufactured pre-2017 would likely fail the new test as the standard hadn't existed at the time of manufacture. Wrenches manufactured to the 2017 standard would also pass 2003 standard testing. The Calibration Select team told me the 2017 test is also at least 90 minutes long, and very thorough, it includes a series of extra tests (approximately 120 test points). This standard really tests the tools to the limits and is more expensive.

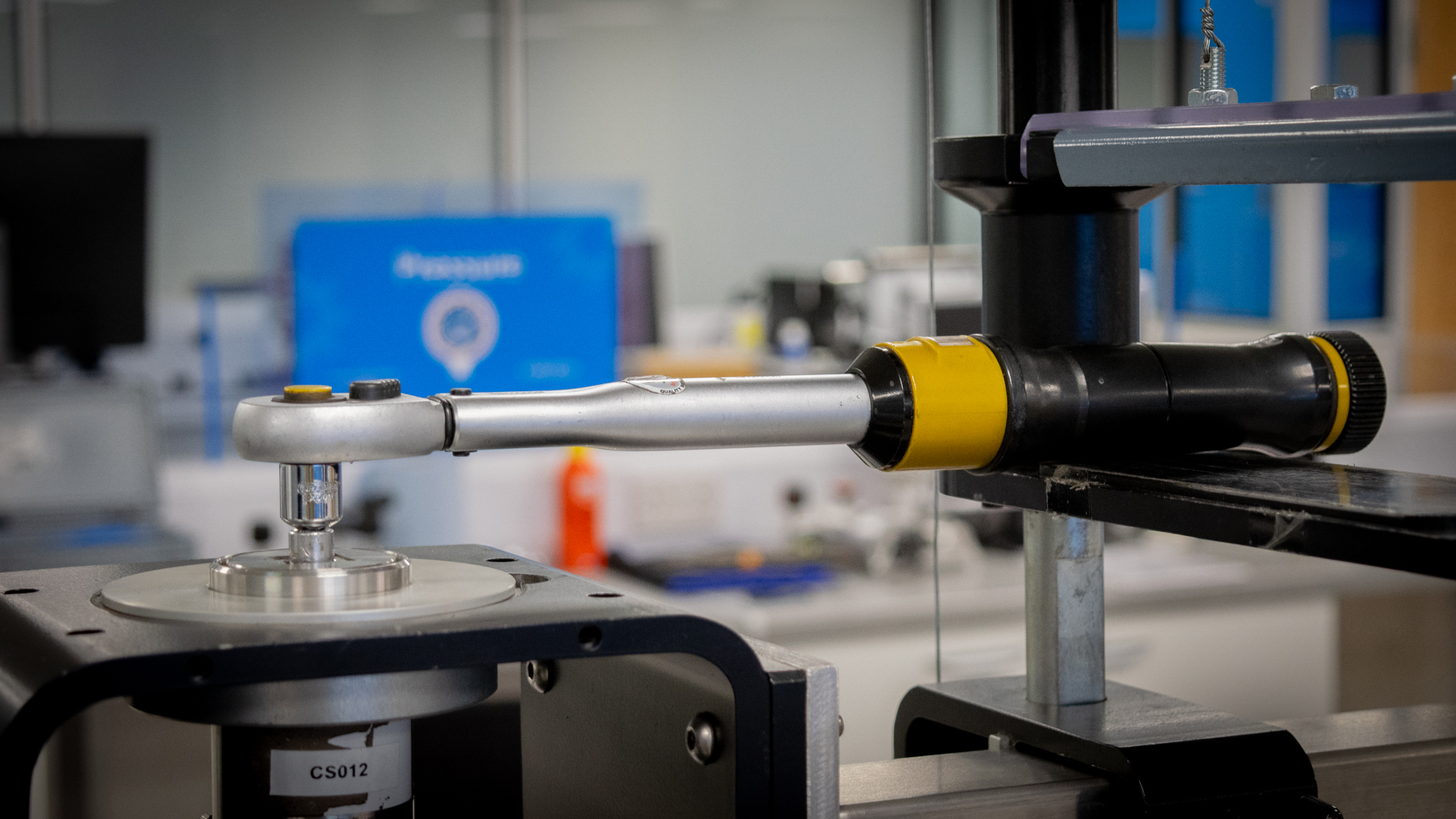

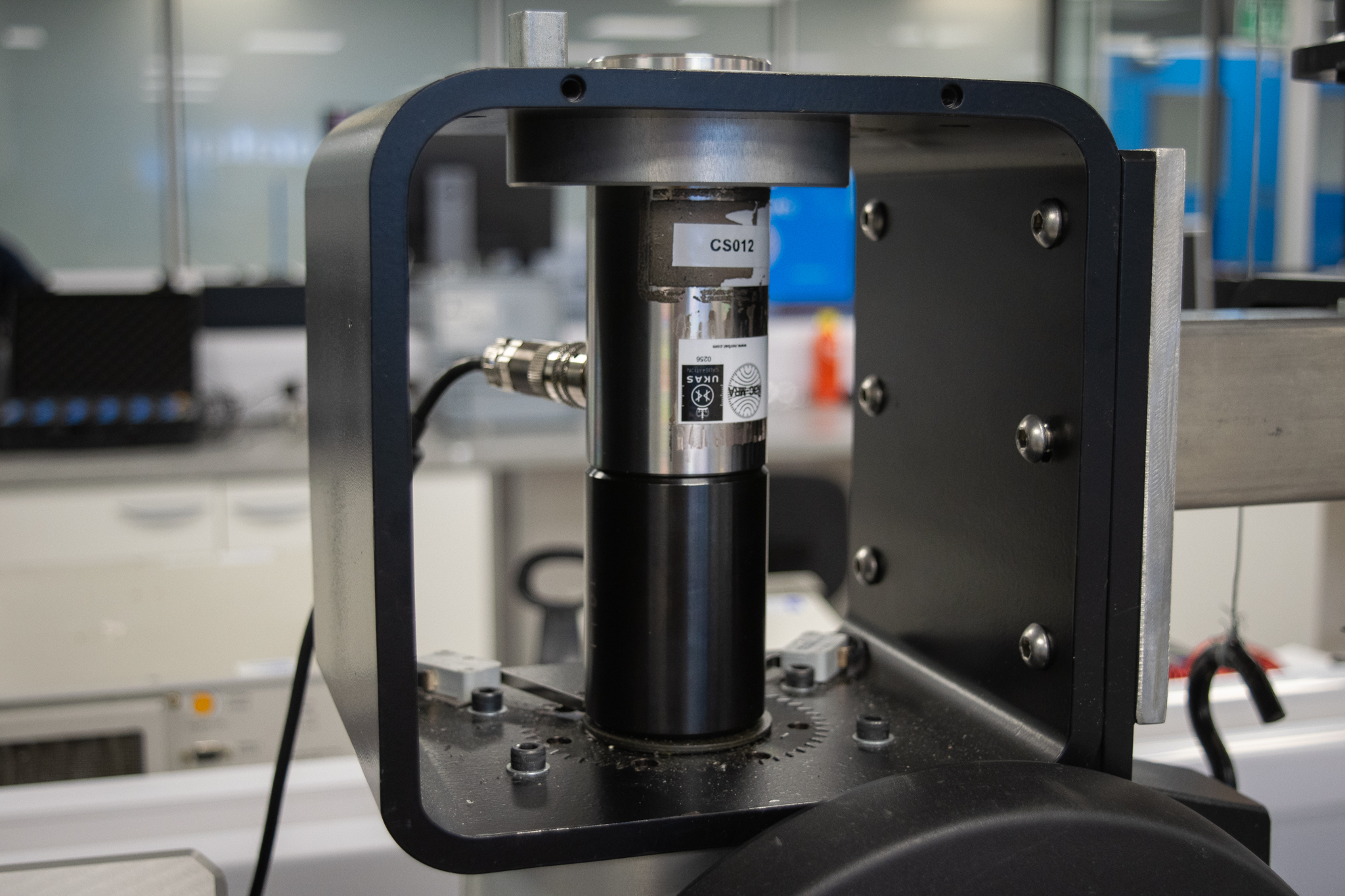

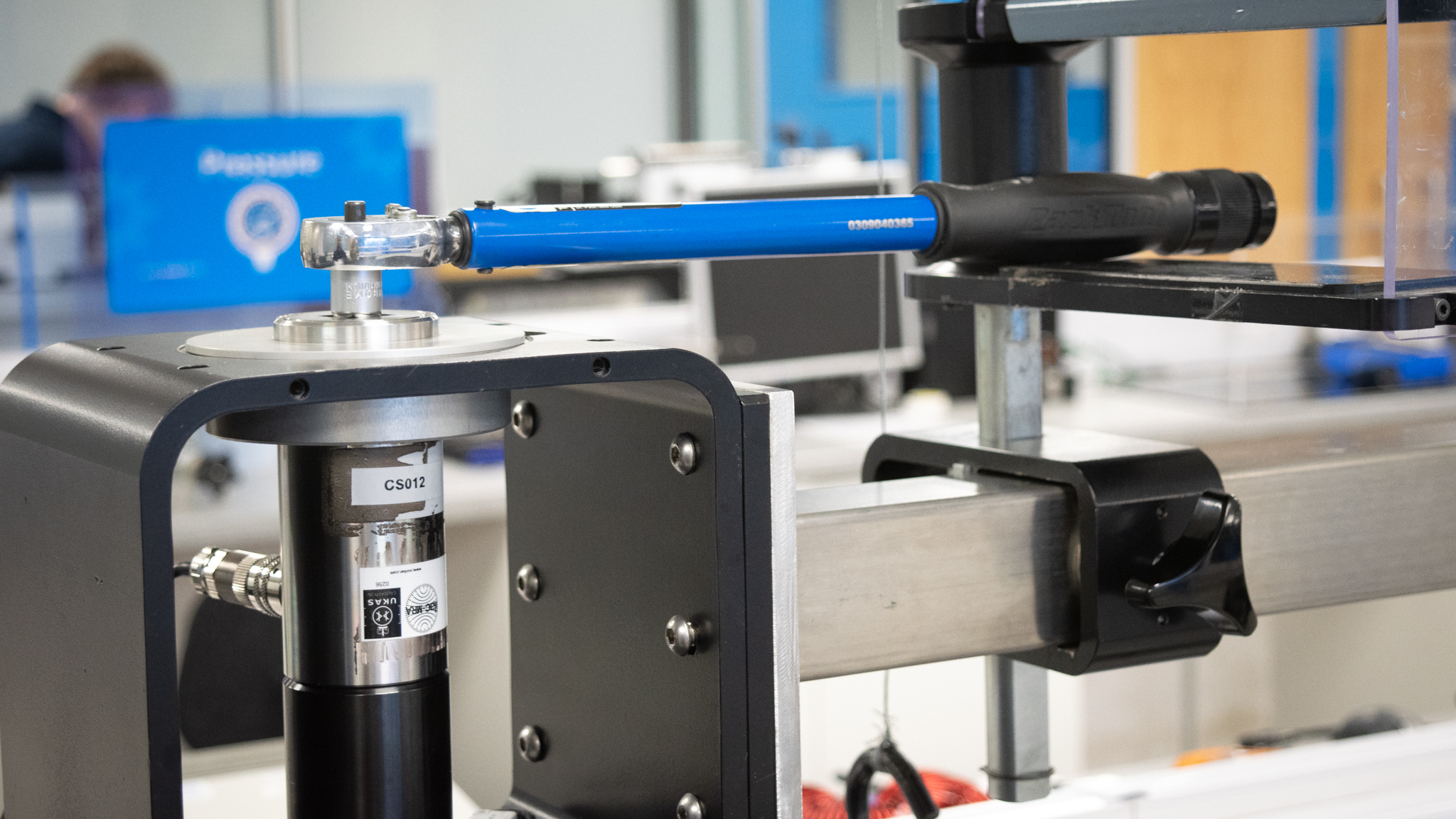

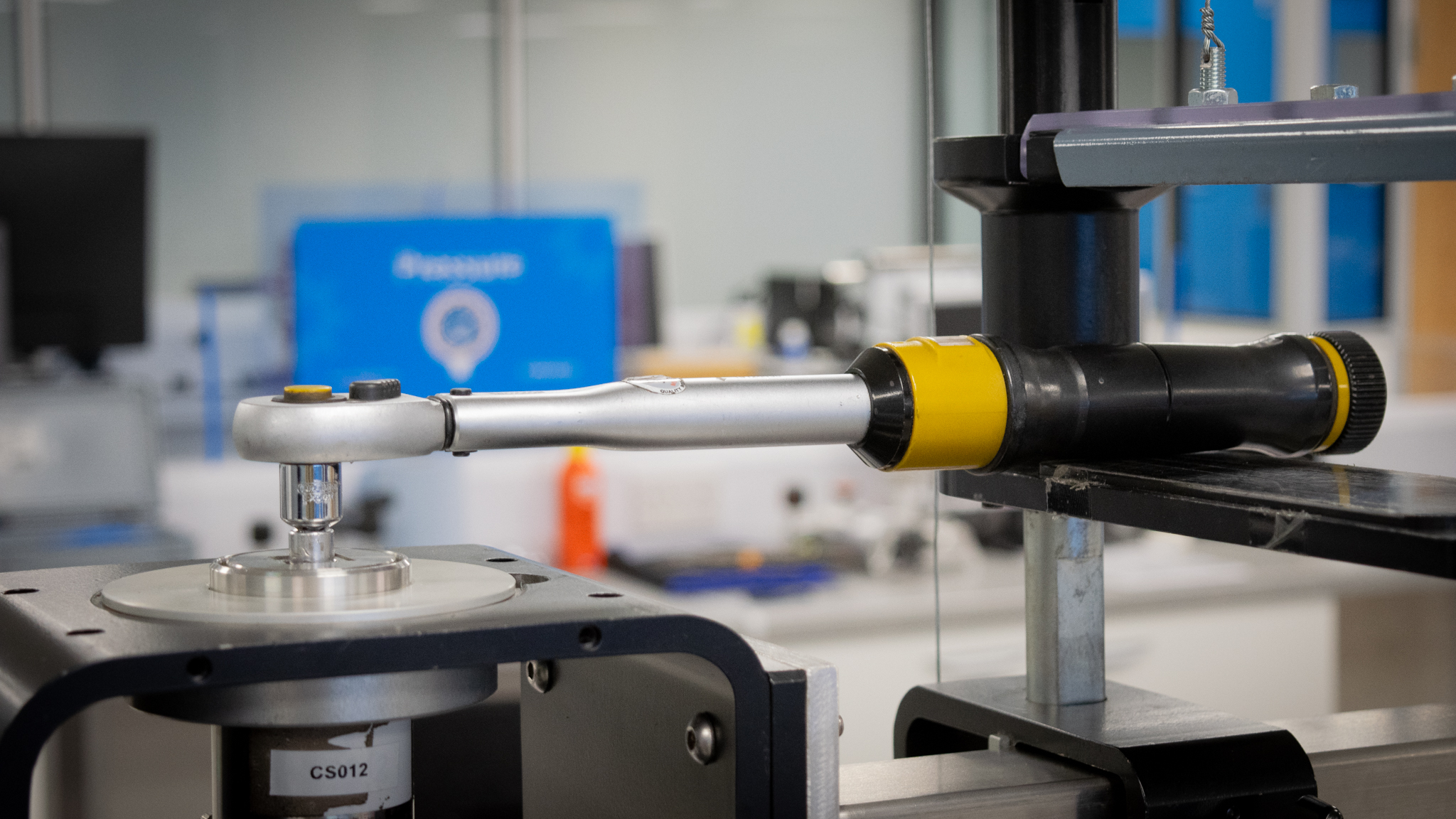

The lab used Norbar testing equipment to carry out the calibrations, themselves a manufacturer of torque tools. The Torque wrenches were calibrated on a fairly large torque calibration rig which could accommodate a range of different-sized wrenches. A quick torque check is performed beforehand on a small Norbar TruCheck machine to ensure a particularly 'bad' or out-of-spec wrench doesn't upset or damage the load cells used on the electronic transducers on the torque test rig. It's a small extra safety step that prevents any unnecessary damage.

Preliminary checks also max-test the wrench to warm up the spring inside. An interesting point was raised here regarding how temperatures can affect torque wrenches' accuracy. So for instance, if you're coming into a cold workshop in the morning a few test clicks are a good thing to do first to warm up the metal the wrench spring is made of. Yousuf explained the first one of the day may give a different reading to later on in the day once the spring is warmed up. So he recommended doing a few clicks first at maximum torque, then torquing the bolt or fastener for maximum accuracy. Is this overkill for torquing a crankset bolt? Possibly, but if you want to be as accurate as possible with a set of $400 carbon fibre handlebars then it's a useful tip.

Once the initial check is complete, to calibrate an adjustable torque wrench the instrument is placed onto the Norbar torque calibration rig. A wrench is mounted to an electronic transducer relevant to the torque range of the wrench being tested. A transducer by definition converts energy from one form to another. Weights are also used to counterbalance each wrench and to ensure each one is flat along two planes, vertical and horizontal (a small spirit level is used for this) this is all about ensuring repeatable measurements are achieved. Depending on whether the 2003 or 2017 standard is being used the lab then performs three test points at different ranges in the torque scale of the tool. Either at minimum or 20%, 60% or Max of the torque wrenches range. Yousuf explained the sternest test for wrenches was often at the lowest end of the torque range. (You can see this test range below in the certificate photos). The lab set each point and then record the error on a UKAS-calibrated indicator. The recorded readings are what the wrench reads when a set torque is applied to it by the transducer. Each torque wrench is then tested five times at each test point for repeatability. At each test point, the technician makes sure they are within the limits stated in BS6789 unless a customer has their own requirements.

The wheel you see in the photos at the front of the rig is wound by hand by the technician, moving the transducer and in turn the head of the torque wrench until the required reading is reached, this is repeated five time so the torque wrench doesn't move (a preconception of mine), and the transducer and technician do the work. The readings are displayed on a digital screen next to the rig which also uses Norbar software. The testing took a while, and I could appreciate how time-intensive calibration for the 2017 standard might be.

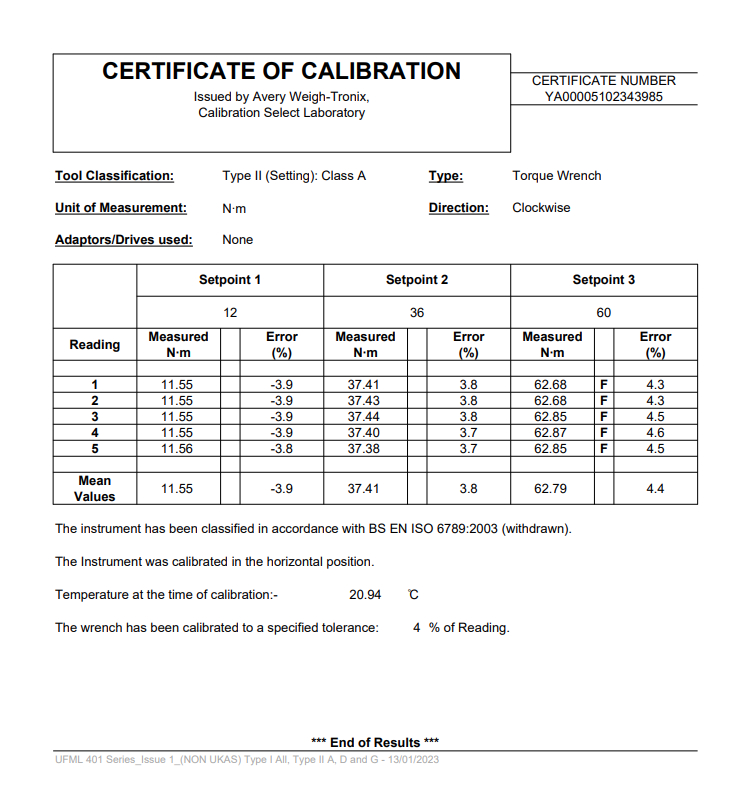

Testing was not as black and white as I thought it was. A range of accuracy can be tested and accommodated depending on how accurate a customer needs things to be. For instance, an aerospace client may have a different set of requirements to me making sure my torque wrench for bikes is still accurate. The lab test is to a standard but can account for an acceptable tolerance range for a customer, though the British standard default tolerance criteria is 4%.

Testing results

After the calibrations were finished we were left with our results. Two out of three wrenches officially failed their calibrations. The Proxxon wrench passed the calibration and the two older Park Tool and Cyclus wrenches failed, but only in certain areas of the overall torque range. Again this was new for me and showed the area isn't just black and white. The wrenches were fairly accurate at certain points of their range and still ok for use, but overall were classified as a fail. Yousuf explained in the event of a failure the lab could provide a quote for a replacement torque wrench or calibrate a wrench over a specific range to achieve a pass.

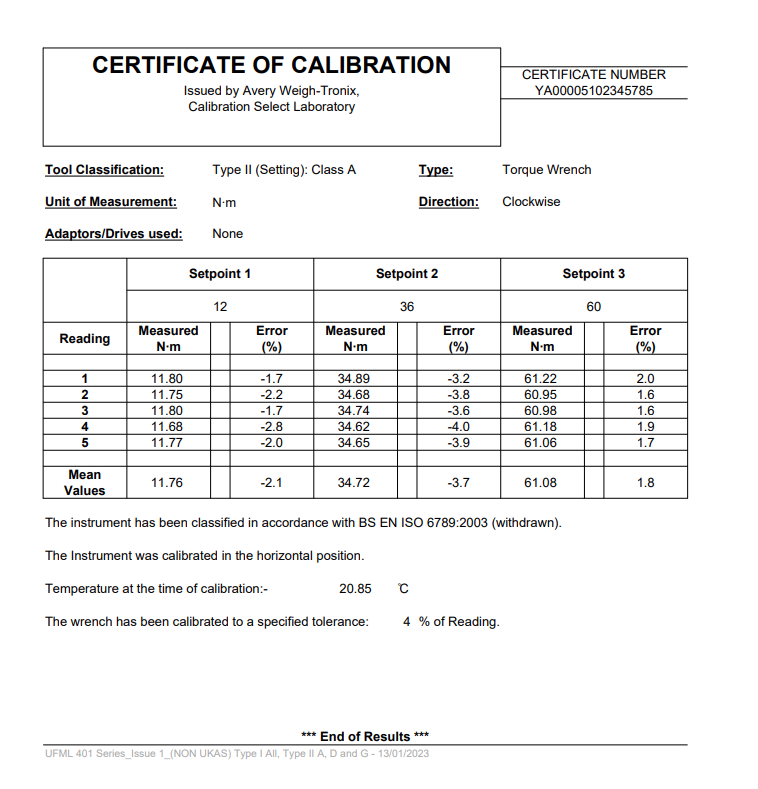

The Proxxon wrench had a range of 12-60Nm and was the newest unit, and despite repeated use was still in spec. It was tested at 12,36, and 60Nm. The mean result for the 12Nm test was 11.76. The mean result from 36Nm was 34.72 and the mean result from the 60Nm max test was 61.08. The poorest result was in the middle of the range, but overall it met the 4% acceptable standard.

The Park Tool wrench was a fairly old unit and had seen a lot of use. It had a range of 12-60N. It failed at the top end of its torque range and was tested at the same range as the Proxxon unit. The mean measurement for the 12Nm test was 11.55. The mean for the 36Nm test was 37.41 and the mean for the 60Nm test was 62.79.

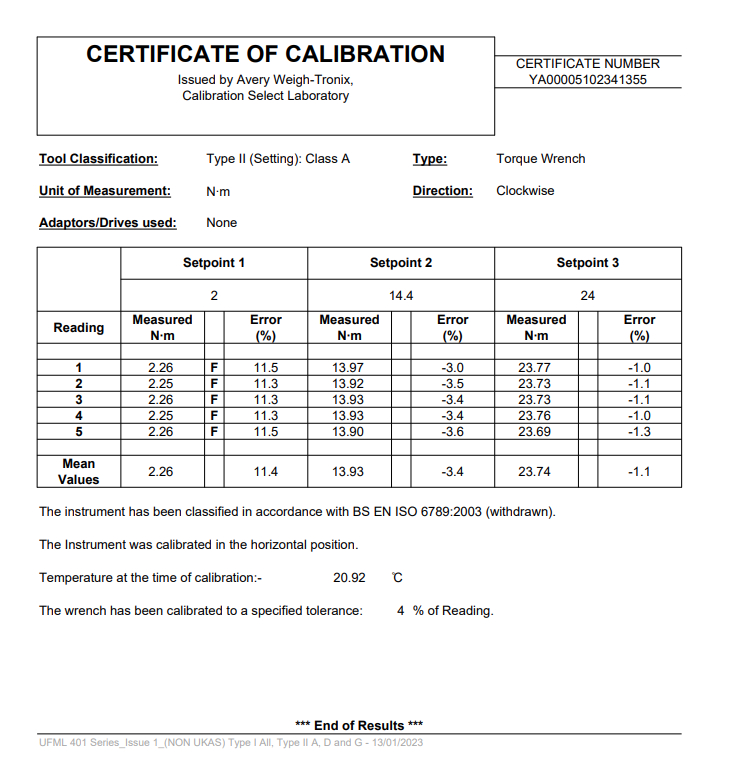

The Cyclus wrench again was a few years old and had seen some use. It had a range of 2-24Nm and it failed at the low end of its torque range, the opposite of the Park unit. It was checked at 2,14.4 and 24Nm. The mean reading for the 2Nm test was 2.26. The mean reading for the 14.4Nm test was 13.93 and the mean reading for the 24Nm test was 23.74.

I don't really know what I expected in the calibration results. I think I expected perhaps far bigger differences compared to the figures produced during the calibration and it highlighted the levels of accuracy the standards work to and the wrenches themselves. Would a torque wrench being out affect a track bike wheel nut that has been properly tightened? Probably not. Would it affect a lightweight carbon stem with a 3Nm torque rating? Possibly. The decision lies with the mechanic or user ultimately.

Conclusions

It was eye-opening to visit a metrology lab and learn more about torque wrench calibration and the process involved. It did feel like something of an endpoint for the topics we've looked at on torque over the last few months. Yes, you could go and buy a new torque wrench and use it for years, but there may come a point where if you don't calibrate it, It may not be giving the same results it once did, potentially running the risk of damaging components.

I think this is also a good time to address the point that often gets raised in some quarters which is usually along the lines of "I work on bicycles, not space shuttles, why do I have to buy a torque wrench, let alone pay to go and get one calibrated". If you've never used a torque wrench and never had a single problem then that's honestly great news, but I think if your working on bikes for other people, an employer or in large quantities then owning a torque wrench, using it, and calibrating it is the difference between hoping something is right and knowing it is.

Bike industry maintenance work doesn't require the same sort of traceability and paper trail that say the aviation industry does when it comes to torque checks and I think this may be the crux of it. Perhaps this is a reason we don't see, or at least hear about as many bicycle torque wrench calibrations being carried out. Bicycle components and materials are also at the top end, getting lighter and more exotic which does require a high level of torque accuracy to avoid component damage or failure compared to say a burly, steel racing bike from fifty years ago.

I'm sure there are pro and home mechanics or employers out there who just want to try and achieve the best, most accurate work possible and have peace of mind that their equipment is looked after and in working order. In this case, I think torque wrench calibration is probably going to be an obvious choice and something they go for happily.

Tom joined the Cyclingnews team in late 2022 as a tech writer. Despite having a degree in English Literature he has spent his entire working life in the cycling industry in one form or another. He has over 10 years of experience as a qualified mechanic, with the last five years before joining Cyclingnews being spent running an independent workshop. This means he is just as happy tinkering away in the garage as he is out on the road bike, and he isn’t afraid to pull a bike apart or get hands-on with it when testing to really see what it’s made of.

He has ridden and raced bikes from an early age up to a national level on the road and track, and has ridden and competed in most disciplines. He has a keen eye for pro-team tech and enjoys spotting new or interesting components in the wild. During his time at Cyclingnews, Tom has already interviewed some of the sport's biggest names including Mathieu van der Poel, Tadej Pogačar and Alberto Contador. He's also covered various launches from brands such as Pinarello, Ridley, Specialized and more, tackled the Roubaix Challenge sportive aboard his own rim-brake Cannondale SuperSix Evo, tested over 20 aero helmets in the wind tunnel, and has created helpful in-depth buying advice relating to countless categories from torque wrenches to winter clothing.