Ceramic bearings: Do you need them for your bike?

To many, ceramic bearings represent the ultimate wheel or drivetrain upgrade, we look at what is available in the ceramic bearing market

When it comes to upgrading components that make you go faster on your bike, many riders' first concerns are about reducing weight or improving aerodynamics, but an often overlooked area of potential improvement is friction. A whole host of products have been launched over recent years that claim to reduce friction and save watts, and ceramic bearings are present in many of them.

Reducing friction has the potential to unlock many gains. Present in your derailleur pulleys, bottom bracket, hubs, pedals and more, superior bearings can ensure that fewer of the watts you expend are wasted in overcoming friction, and more of them end up creating forward momentum.

There are few things more annoying in cycling than having a bike that has been immaculately configured, but with imperfect bearing rotation in the drivetrain, bottom bracket or wheels. You can feel those watts go to waste with every rotation of a sticky bearing.

We rely on steel for many things in cycling: spokes, chains, frames, axles and bearings. But is there a better bearing out there to make your ride even smoother? The answer could be ceramic.

- Road bike groupsets: A complete overview of today's best groupsets, no matter your budget

- Best road bike wheels: Our pick of the best wheelset upgrades

Ceramic bearing bottom bracket upgrades

FSA K-Force PF30/BB386

Specifications

Reasons to buy

To prevent an early increase in rotation friction from your road bike bottom bracket, FSA offers a range of ceramic bearing upgrades, with increased durability.

The MegaExo K-Force is packed with ceramic bearings that should last much longer than steel. This bottom bracket is also optimised for use with electronic shifting drivetrains, specifically DI2, thanks to a composite centre sleeve.

If you are running the Shimano electronic shifting system and want it to be perfectly calibrated with your pedal stroke, FSA’s ceramic bottom bracket is a great enabler.

CeramicSpeed BB30

Specifications

Reasons to buy

Reasons to avoid

The Danish brand started out with in-line skating and has become synonymous with integrating ceramic bearings into cycling components.

CeramicSpeed closely guards its bearing production, which remains proudly Danish. Even as the company has grown, CeramicSpeed resisted the lure of contracting its production to an offshore supplier.

Recognising that bottom brackets are one of the most popular ceramic bearing upgrades, CeramicSpeed produces a selection of its own, compatible with most of the larger brand standards. Whether your ride SRAM, Shimano or Campagnolo, there is a CeramicSpeed bottom bracket that will match requirements.

The claims are impressive, with CeramicSpeed’s bearing being 400 per cent smoother and 58 per cent lighter than a steel equivalent. Ensuring that its bottom brackets spin with the least possible friction, even after a winter season of riding in foul weather, is CeramicSpeed’s low-viscosity grease.

Known colloquially as ‘blue grease’ by CeramicSpeed followers, it’s a vital part of what makes the Danish bottom brackets last longer and spin smoother.

Kogel ceramic BB

Specifications

Reasons to buy

Reasons to avoid

Similar to FSA and CeramicSpeed, this American bearing specialist has a broad offering of bottom brackets. What makes Kogel interesting are its diverse seal options and some of the design details, applied to its bottom brackets.

For both professional and amateur mechanics, fitting and servicing these bottom brackets should be effortless. No adaptors are required and the internals are easily accessible when you need to eventually replace the bearings or seals.

On the topic of seals, Kogel has a choice of ‘road’ or ‘cross’, with the former promising lower friction and the latter, superior environmental sealing. This is especially valuable for riders who keep training through inclement winter weather, when a bottom bracket is most at risk of ingesting moisture and road grit.

Engineers and industrial designers at Kogel, have also ensured that the ceramic bearings are closely stacked to the bottom bracket flanks, increasing stiffness and reducing leverage wear from your crank arms.

Keen to protect your output in watts and ensure negligible wastage, the Kogel ceramic bottom bracket bearings spin in mirror-polished races.

C-Bear BB30

Specifications

Reasons to buy

Reasons to avoid

C-Bear might have a name and logo that symbolise California, but it is a Belgian brand, with an immense ceramic bottom bracket offering.

Founder, Bart Schouten, isn’t afraid of investing time and resources in prototyping. The result is a ceramic bottom bracket portfolio that is very intuitive to fit and maintain.

Riders can choose either a race or cyclocross configuration, depending on their requirements for speed or ultimate durability in wet conditions. C-Bear also sources an appropriately formulated grease to support their race and cyclocross seal kits.

An impressive design feature on C-Bear ceramic bottom brackets is the aluminium cup and housing. Schouten prefers using metal in this area on his brand’s bottom brackets, instead of a plastic housing.

The fitment of your C-bear bottom bracket is also eased by the absence of superfluous spacers, wave rings and adapters.

The best ceramic wheel bearings

CeramicSpeed wheel bearing kits

Specifications

Reasons to buy

Reasons to avoid

We have all spun the wheel of a bike that is clamped in the work stand, to see how long it will keep rotating.

CeramicSpeed hub bearings can reduce friction at the heart of your wheelset.

The company has nearly every OEM wheel brand covered, but if you are riding a boutique wheelset, CeramicSpeed can help with some custom configurations.

How much of a gain is there with the CeramicSpeed wheel kits? Durability is core appeal, with CeramicSpeed wheel bearings conservatively rated at three times the longevity of traditional steel bearings.

You have the option of upgrading to CeramicSpeed’s coated wheel bearings, which spin with even less friction and prove more robust.

The Danish company has great confidence in its ceramic bearing wheel kit, offering a four-year warranty of all standard bearings, with six years of product assurance of the coated bearings.

Kogel ceramic wheel bearings

Specifications

Reasons to buy

Reasons to avoid

Kogel’s polished steel races and grade-three ceramic bearings can also do service in your hubs. Riders have a choice for ‘road’ or ‘cross’ seals, similar to the brand’s bottom brackets.

Easy to install and service, the Kogel wheel bearing kits are also supported by a two-year warranty. Riders who do their own maintenance will also be pleased that Kogel sells its wheel bearings in sets of four, five or six.

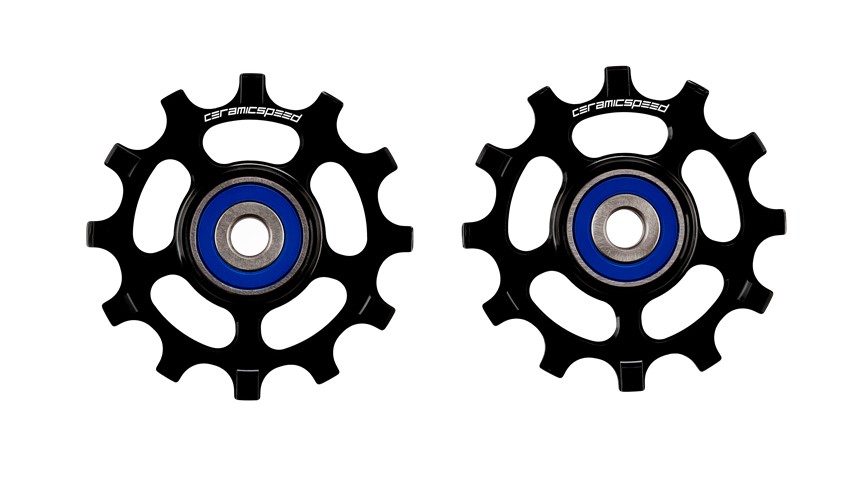

Ceramic derailleur pulley wheels

CeramicSpeed pulley wheels

Specifications

Reasons to buy

Reasons to avoid

Some of the smallest bearings on your bike, but as they support chain movement, they're also crucial.

Pulley wheels run on tiny bearings and although they rarely have to contend with side-loads, they do spin and face the elements. A metallic coating applied to the bearing races helps to protect these ceramic pulley wheel bearings from contamination.

CeramicSpeed’s pulley wheels are compatible with most nearly any Shimano, SRAM and Campagnolo drivetrain you can imagine.

The Danes have kept developing their ceramic pulley wheel offering, reacting swiftly to new drivetrain releases.

With a six-year warranty on their coated pulley wheel bearings, you will probably have to replace the chain, cassette and chainrings a few times, before your rear derailleur internals are even worn in properly.

- Object of Desire: CeramicSpeed 3D-printed Ti OSPW system

Muc-Off LOPS

Specifications

Reasons to buy

Reasons to avoid

Muc-Off is best known for its bicycle cleaning and care products. But the company has also ventured into the boutique rear derailleur business.

Its Lightweight Oversized Precision Shifting (LOPS) rear derailleur is the absolute last word in low-friction drivetrain upgrades.

Designed in conjunction with Mikel Landa, it features a 13t upper and 19t lower pulley wheel assembly, creating superior chain tension. Instead of carbon fibre, the cage is 3D-printed titanium.

Muc-Off has also coated the ceramic bearings in a very low friction lubricant, to dramatically minimise any residual friction.

There is no official price and environmental sealing might be questionable, but as an example of pure low-friction drivetrain technology, the Muc-Off LOPS is deeply impressive.

The big question: durability or speed?

Ceramic bearings are marketed primarily for their reduced friction properties. The material composition and production methods applied to ceramic bearings, make them more spherically perfect than is possible with a steel equivalent.

Rounder bearings mean better tolerances, and when you see how tightly spaced and packaged certain bearings are, that makes a big difference. With a truer shape, the ceramic bearing also contacts its surrounding surfaces as engineers intended, reducing friction and the wear associated with slight misalignment.

But how much friction do they save? This is the vexing question about the logic of a ceramic bearing upgrade. The amount of energy you save is not massive if you replace the steel bearings in your hubs, bottom bracket and pulley wheels with ceramic.

Although any friction reduction does compound the longer your rides become, a ceramic bearing upgrade might not be that noticeable.

The issue with ceramic bearings is that cyclists simply cannot generate the cadence to really draw a benefit from the material properties inherent to ceramic bearings.

It is worth noting that the original design intention for ceramic bearings, applies to very high-speed applications: beyond 20,000rpm. With most riders rarely exceeding even a hundredth of that in their cadence, the friction difference between a steel and ceramic bearing at low rotational speed isn’t much.

Where the ceramic bearing does promise value, is its longevity. These bearings are usually a third harder than steel and because of their superior roundness, the risk of deforming over time (under load), is reduced.

Skillfully packaged and produced ceramic bearings can easily last five times longer than steel and they don’t rust. This is a notable benefit to riders who remain committed to their training volumes throughout the year, regardless of the weather.

Expensive but exceptionally durable. If you ride huge mileages the cost of a ceramic bearing upgrade should amortize over time.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Lance Branquinho is a Namibian born media professional, with 15-years of experience in technology and engineering journalism covering anything with wheels. Being from Namibia, he knows a good gravel road when he sees one, and he has raced some of Africa’s best-known mountain bike stage races, such as Wines2Wales and Berg&Bush.