Campagnolo reveals new 2007 groups

Campagnolo has launched its new groups for 2007. The poorly-kept Ultra-torque bottom...

Tech feature - July 12, 2006.

Campagnolo has launched its new groups for 2007. The poorly-kept Ultra-torque bottom bracket/crankset secret is finally out. Campagnolo have finally ditched their square-taper design in preference for a splined system that is much more commonly used by other manufacturers. Pleasingly, the Ultra Torque system will be available on all of their groups, barring Xenon. The other big design change from 2006 is the Skeleton hollowed-arm brakes. John Kenny checks out Campag's new gear for 2007.

The main Campagnolo changes for 2007 are focused around the bottom bracket, crankset and the brakes. Probably the most significant change is Campag's abandonment of the 'trickle down' policy where techological changes affect Record first and then filter down over the years to the cheaper groups. The significant changes for 2007 are across the board. All groupsets are now available only in 10-speed and all 2007 cranksets barring Xenon will have the Ultra-torque design and the new 'Skeleton brakes' will be included from Veloce upwards.

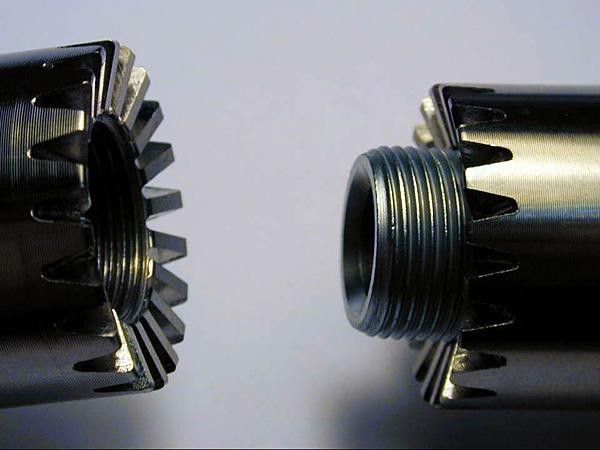

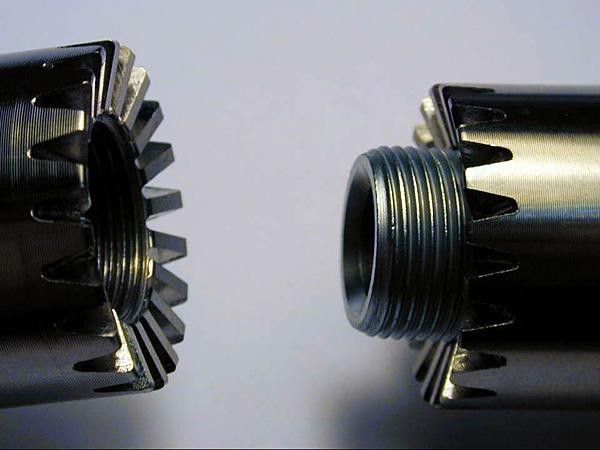

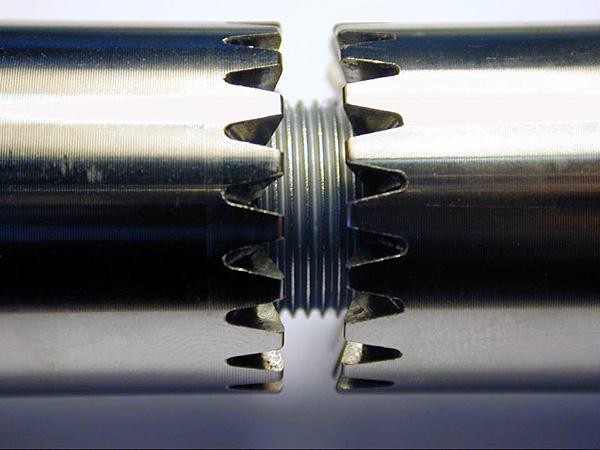

Ultra-torque system

The Ultra-torque system, along with the skeleton brakes, represents the biggest departure from conventional Campagnolo design. The old square-taper axle is gone after decades of faithful service and is replace with a combined bottom bracket/crankset system. The new system is lighter than Record 2006 and is significantly stiffer. According to Campagnolo, the Record and Chorus models are also torsionally stiffer than their main competitors. The 'Q-factor', the distance between the pedals, remains the same as on the old models. This is important to keep riders knees tracking properly.

Those who have tried fruitlessly to get the bearings out of some of the rival systems will be pleased to see the accessability of outward bearings. They're easy and comparitively cheap to replace. Campagnolo also say that they last longer.

Skeleton brakes

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

The Skeleton brakes are quite obviously going to be lighter than the previous design as sections of the arms have been carved out. It's a radically different looking system and has an almost retro appeal. Older readers will recall a time when riders would fastidiously carve and drill out section of their components in the name of lightness. Unfortunately strength was normally compromised as well.

So how has Campagnolo maintained the integral strength of the brakes? Campagnolo conducted a study where data recorders were mounted to a bike to determine where the areas of greatest stress were on the components. The component areas that had unnecessary bulk for the job they were doing were carved out. According to Campagnolo's Francesco Zenere, "That study gave life to the design of the Skeleton brakes which have increased rigidity at the points of greatest stress while the material is lightened where there is no stress. This new design led to a reduction in weight and a gain in performance."

Campagnolo have also forged the brake arms rather than using CNC technology. The reason that Zenere gives for this is that, "Forging maintains the micro-crystalline structure of the aluminium alloy… and this is the main factor in the life of a component. This is not the case with CNC machining which, on the one hand, makes it possible to realise lighter components with attractive forms, [but] breaks the structure of the alloy and makes the component more vulnerable to the phenomena of cracking and breaking with fatigue."

Skeleton brakes maintain the differentiated design that the company has used since 2002. The single-pivot design of the rear brake save weight and does not affect braking as the front brakes are responsible for most of the stopping power. The back brake is also less likely to lock under extreme braking with it's single-pivot design. Campagnolo did another one of their studies and found that the new design was safer. "It was in fact noted that, as there was no risk of locking the rear wheel, the cyclist can act on both brakes without concern and stop the bike without the risk of dangerous swerving. This is the reason why all Skeleton brakes are of the differentiated type," said Zenere.

The Quick Shift utilised on the groups apparently helps shifting under load, while the new 'escape' mechanism helps with maintenance, although this would be much more obvious with a dismantled lever.

Record

The flagship Record groups must share it's changes with its lower-end brothers for the first time, but the main changes are lighter and more exotic than the others in the range. However, the Ultra-hollow crankset is unique to Record and Chorus. The other groups get the Ultra-torque part of the design, but do not have hollow crank arms. The new Record crankset is 89 grams lighter than last year's model. There is no longer an aluminium crankset option. The longer crank arm lengths of 177.5mm and 180mm are only available on the Record group.

New Skeleton brakes are 33 grams lighter than the old model, with the same stopping power as before. The combined weight of the hubs is 29 grams lighter than before.

Chorus

The new Chorus crankset is 85 grams lighter than before and is also no longer available in aluminium. The Skeleton brakes are 36 grams lighter, the Ergopower levers and derailleurs get the Quick Shift system and Chorus users will get Record hubs as part of the group. The ability to 'dump' down multiple gears in one hit will be available only to Record and Chorus users. The lower groups will change down by a maximum two cogs at a time.

Centaur

Centaur now gets a bit more carbon - on the Ergopower levers and the rear derailleur body. The levers are 70 grams lighter thanks to the use carbon and the simpler Escape mechanism (that also restricts multiple downshifts). The Ultra-Torque crankset is only available in aluminium. Also new are the CNC-machined aluminium sprockets which Campagnolo say further enhances the shifting. The Ultra-Torque Centaur crankset is available with traditional and compact chainrings, nominally 39/53 and 34/50. Centaur also gets a new 11-25 cassette. The new combination is designed to complement compact crankset users as it provides broader range of ratios.

Veloce

Veloce get the Ultra-torque and Skeleton parts and is available in two colours - a black finish and the impressively-named silver, 'Veloce Infinite'. The aluminium crankset will only be available as compact; with 39/53 or 34/50 chainrings. Veloce is the final group in the range to get the Skeleton brakes. The Ergopower levers are the Quick Shift type and are fitted with Campagnolo's simpler Escape mechanism. Veloce also gets the 11-25 cassette.

Mirage and Xenon

Mirage gets the new 10-speed flat bar Ergopower controls and is the final group to get the Ultra-torque crankset. The Ergo levers are 52 grams lighter than the previous version. The new hubs are also lighter by 100 grams. Xenon's crankset gets an ISO type bottom bracket and a compact drive-ready front derailleur. The Mirage and Xenon rear mechs are available in short, medium and long cage. The Xenon group will use Mirage's brakes, hubs, sprockets and Quick Shift front derailleurs and Veloce's chain.

Triple groups

The triple groups are now completely separate to the double groups and are re-named Race, Comp and Champ. All three groups use ISO type bottom brackets, have 170 or 175 mm crank arms and typically are supplied with 30-42-52 chainrings. The triple groups use the 111 or 115.5mm Mirage bottom brackets.

Electronic shifting?

The electronic shifting derailleurs that have been in development for the past four year are still a while away from mass-production. Campagnolo Australia's national sales manager, Jonathon Nunan, said that he is often asked when the electronic parts will become available, "Many people ask me why they haven't released it yet when they've seen it being used in the Pro races, and in fact has already won some major races? Well, in true Campagnolo form, they won't release anything until it's 100 percent developed and proven. Part of that is longitudinal testing that they insist on."

Campagnolo trade on their reputation for reliability and quality, something that could be compromised if they released an electronic group that had not been properly tested, "What Campagnolo don't want, is something that develops problems after thousands of kilometres or years of race-level usage. After all, Campy is famous for it's reliability and dependability, and there are just too many potential pitt-falls when it comes to this kind of technology," said Nunan.

The other major delay for the Campagnolo electronic parts, is changing and improving battery technology, with which Campagnolo is struggling to keep up. "As the long-life batteries get smaller and lighter, Campagnolo are constantly redesigning their components and systems to facilitate these new batteries," said Nunan. "When Campagnolo come to the market with electronic, they want it to be functionally attractive, but also appealing from a weight point of view. No matter how clever, it won't be taken up it is heavier than a conventional gruppo."

Campagnolo's electronic group V2.0

Eeckhout wins on Campagnolo Electric

More Campagnolo Electronic

Bikes of Paris-Roubaix 2005

Campagnolo's test pilot