Canyon's incredible Projekt MRSC Connected concept road bike

Slick electronic dual suspension, disc brakes, thru-axles, and aero shapin

This article originally appeared on BikeRadar

Canyon has a long history of showcasing some very forward-thinking concept machines at the annual Eurobike show. This year, the German consumer-direct powerhouse offered up its vision of the ultimate high-performance road bike called Projekt MRSC Connected, complete with an advanced electronically controlled suspension, disc brakes, thru-axles, aero shaping, two-way communication, and a beautiful design that might even convince the most hardened skeptics.

Even better, the Projekt MRSC Connected isn't just some pipe dream fantasy. Canyon already has a functional development mule undergoing testing – and we even got to ride it, too.

Canyon's Projekt MRSC Connected concept is quite ambitious but the design goals are nevertheless attainable

Magneto-Rheological Suspension Control

Although the bike's disc brakes, thru-axles, and overall styling are all interesting in their own right, the heart of the Canyon concept machine is its very clever suspension system, which is designed to provide up to 15mm of vertical wheel travel at either end controlled by lightweight carbon fibre leaf springs and very compact, electronically controlled magneto-rheological dampers.

Wait, magneto-what?

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Magnetic particles suspended in the damper fluid allow for near-instant changes in viscosity

Much like any standard oil-based damper, magneto-rheological (MR) dampers work by restricting the flow of a fluid in order to absorb energy. Instead of the typical viscous oil, though, MR fluid is actually a suspension of magnetic whiskers. Applying an electronic current to that fluid changes the orientation of those whiskers, thus changing the effective fluid viscosity and the associated damping characteristics.

Automobile companies already successfully use MR dampers to constantly adjust suspension performance to suit changing road conditions and Canyon hopes to accomplish the same goal here. Canyon tells us that the system can alter itself in just one one-thousandth of a second and requires very little power. Moreover, combining that adjustability with onboard sensors can potentially make for a truly intelligent system that can provide tangible traction and rider comfort benefits.

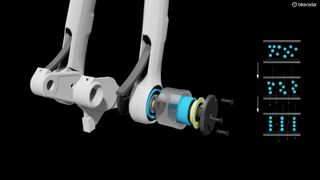

The rotary-style dampers are quite compact

The possibilities are essentially only limited by the sophistication of the surrounding electronics. Accelerometers in the fork and seat tube could detect bumps and soften the dampers to absorb the impact before a rider even feels them. Road texture could be translated into a vibration frequency, which can be canceled out by properly timing the applied current. Pressure sensors in the bars could discern when a rider is sprinting and leave the dampers locked out completely.

Despite the sophistication, Canyon has gone to great lengths to package all of this into a form that still looks like a somewhat 'normal' road racing bike.

Instead of the linear, reciprocating-type dampers that are more commonly used in bicycle suspension systems, Canyon uses more compact rotary-style units that are cleanly integrated into the rest of the structure. Meanwhile, ultralight carbon fibre leaf springs are used all around, which are not only tunable for preload and spring rate but naturally produce a progressive spring rate by virtue of how they're mounted.

On the concept, the green strips is the carbon fibre leaf spring while the round bit is the damper, which is wholly housed within the seat tube

And although there are conventional pivots for the fork, there are no pivots needed for the rear end given the limited travel, which decreases weight and minimizes any sacrifice in stiffness. Instead, flex points are designed into the chain stays, which are positioned in between the inner and outer chainrings height-wise to minimize pedaling effects on the suspension.

Finally, Canyon claims the MR system requires very little power, too – all of which is conducive to a small, lightweight, and compact system that hopefully wouldn't turn an elegant bicycle into some sort of tech-laden Frankenstein's monster.

The design goal is for just about all of the electronic bits to fit inside here

Two-way connectivity via Deutsche Telekom

As if all of that wasn't enough, Canyon has partnered with mobile phone giant Deutsche Telekom (the parent company of T-Mobile) to create a clever two-way communication system that's also hidden away inside the carbon frame.

Using both GPS and some sort of cellular receiver/transmitter (be it GSM, CDMA, GPRS, or some other common wireless protocol), the system can record your rides just like satellite-enabled computers from Garmin, Magellan, and others. Moreover, Canyon says its system could use accumulated mileage data to actively inform the bike's owners as to when certain components should be replaced, such as chains, cassettes, and brake pads – and then not only provide a way for those owners to instantly order replacements (and requisite tools) but show them via transmitted videos how those components should be installed.

Canyon's concept bike would alert you when parts are needed and could also contact emergency responders if a crash is detected

The suspension system's on-board accelerometers could also detect when the rider has crashed and use the system to alert emergency responders, or provide tracking information if the bike has been stolen – all via a convenient smartphone app.

The bike of the (not so distant?) future

Canyon isn't ready to offer any sort of estimates as far as when the Projekt MRSC Connected might actually become a real product but its for-sale date might come sooner than many of us would have thought. While there are obviously a lot of challenges to work through, there's already a test mule to develop the MR suspension system that we got to ride briefly during the Eurobike show.

Canyon already has a development mule undergoing testing

Unfortunately, the pavement immediately surrounding the convention center was far too smooth for a test like this and we couldn't feel the full effects but we could tell that it was working – and that such technology had enormous potential.

In the meantime, Canyon has promised to keep us updated on continuing developments and we're certainly very eager to see where this goes. Canyon is quite optimistic but only time will tell just how closely the finished product will resemble the rather attractive concept, how much it'll cost, and how heavy it'll be. But we definitely can't wait to find out.

The rear end can be made without pivots since there's just 15mm of wheel movement on tap

Most Popular