Closer look: Shimano Dura-Ace Di2 transmission

Calling all skeptics... electronic shifting is the real deal

"A solution to a problem that doesn't exist..."

"Unnecessary..."

"A marketing gimmick..."

Those are lines offered time and again by armchair critics of Shimano's new Dura-Ace Di2 electronic drivetrain yet few of those pundits have spent much - if any - time on the stuff. After our initial sampling last summer in Japan and now two solid months of near-continuous use on a proper test group, we can confidently say that shifting-by-wire doesn't just work; it's flat-out awesome.

Shifting performance that's second to none

Di2's most obvious benefit is its remarkably smooth and precise shifting action, even as compared to the most ideally adjusted and tuned mechanical setup from Shimano or any other component manufacturer - yes, even Campagnolo. It hits its target each time, every time, and absolutely, positively nails each gear without fail in virtually any condition. If there's such a thing as a tireless 'shift robot', this is it.

Tap the rear upshift button and you're rewarded with that telltale 'ka-chunk' of a perfectly executed change. Go a step in the other direction and the transition is so seamless as to be virtually imperceptible save for the feeling in your legs of an easier ratio. In fact, it's almost too smooth.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

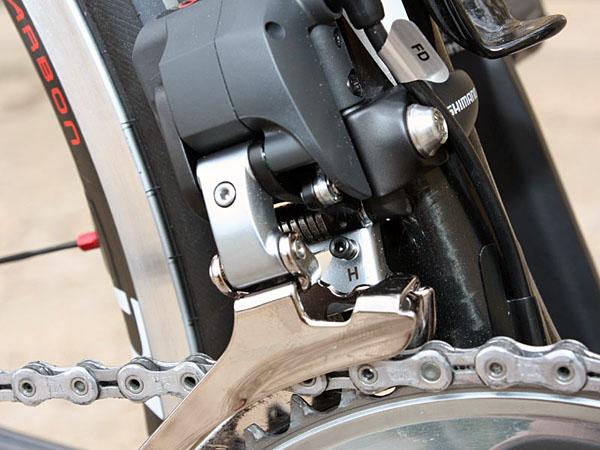

Shift action is especially astounding up front, particularly when used in combination with Shimano's ultra-stiff Dura Ace chainrings. The Di2 front derailleur faithfully moves the chain onto the big ring - or down to the inner cog - even when mashing the pedals in a low-cadence grind with an uncanny silkiness we've experienced with no other system. Think about how well one-tooth shifts work out back, translate that up front and you've pretty much got the idea.

Even better, however, is that Di2's performance is unflappably repeatable and doesn't degrade over time. Commands issued by the levers are always received and translated exactly as intended at the other end with no 'telephone effect' that can plague cable-actuated systems as a result of cable wear, housing compression, or system contamination. Barring things such as a bent hanger, what you get on day one is seemingly what you get for every day afterwards.

Is it possible to confuse the system? Yes, but only if you're really trying to. The only way we could get Di2 to miss a step was by doing things we'd never consider doing anyway and even then it sorted itself out impressively quickly.

Weight-wise, there's only a modest penalty to be paid. In comparison to the 7900 mechanical analogue, Di2 only adds about 50g by our measurements - right in line with Shimano's claims.

Why it works the way it does

The key, of course, is the small stepper motor in the front and rear derailleurs that precisely controls their movements but it's not necessarily a matter of how fast they move - in fact, the front derailleur actually moves slower on average than its mechanical equivalent. Instead, Di2's advantage lies in the fact that it does things automatically that would be impractical on mechanical systems.

For example, Di2's rear derailleur pulleys actually overshoot the centerline of each cog slightly to help nudge the chain into place - but only momentarily. After a very brief pause, it then centers itself for quieter running. In theory, you could do this with a mechanical system, too, and in fact most already do for downshifts anyway. But Di2 does it in both directions, which just isn't possible with conventional ratchet internals.

On the other hand, the front derailleur applies just the right amount of pressure so that the chain moves only at its prescribed gate instead of possibly overriding the designated timing by just muscling it over. Again, you could do this with a mechanical system, too, but it'd required you to precisely apply the appropriate amount of force at the lever and then hold it there until the shift is completed - not exactly ideal in the heat of competition. With Di2, you just hit the button and it does the thinking for you, reliably hitting the next available gate.

It's the same story in the other direction as well. Instead of a strong return spring abruptly jerking the chain down at an inopportune position, Di2 smoothly coaxes the chain down to the inner ring at the prescribed release point. Admittedly, Campagnolo's Ergopower system is capable of this as well unlike mechanical systems from SRAM or Shimano but again, with Di2 it's only a matter of hitting a button - no extra thought required.

A word on shift speed, too: modern drivetrains rely more than ever on their highly engineered systems of gates, ramps and pins to help move the chain from gear to gear and Di2 is no exception, especially given that it shares its crankset and cassette components with Dura-Ace 7900. As a result, 'shift speed' is strictly speaking more a matter of how quickly the chain encounters one of those gates when a shift is initiated than how fast the derailleur moves, making Di2 no quicker than anything else.

But from a user standpoint, Di2 is still effectively faster since once your job is completely done once you hit the button - at least for single shifts. There's no holding the lever for that split second while the shift is completed or ever-so-slightly nudging the chain over with a hair more force. With Di2, it's tap, shift, tap, shift - and that's it. It's a subtle distinction and one that riders who haven't tried Di2 for themselves will invariably debate but it's real and noticeable.

Multiple shifts, however, require multiple button pushes. As fast, precise and smooth as Di2 is, it still can't beat some of its mechanical competitors that can execute several shifts with a single lever sweep. And yes, Campagnolo fans, Ergopower definitely wins here.

Ergonomics

With no mechanical guts to occupy a bunch of room in the lever bodies, Shimano engineers had fewer restrictions in crafting their shape. As a result, the Di2 levers are slimmer in width and smaller in girth than 7900 and have more gently rounded corners that feel more natural in your hands. In fact, they're a much closer approximation of the previous Dura-Ace 7800 generation but thankfully without the sharp dip in the top surface.

Shift button placement closely approximates the mechanical analogue for a reasonably easy-learning curve for current Shimano users, at least when on the hoods. Here, the buttons' fore-aft offset is a familiar layout and their differentiated height and texture are easy enough to tell apart. When in the drops however, Shimano users accustomed to reaching up for the inboard paddle and to the very tip of the main lever to shift in the opposite direction will be caught out a bit.

Instead of the familiar top-bottom layout, you again have the same fore-aft button offset - the main lever is stationary and you can push on its tip as much as you'd like but it's not going anywhere. In this situation the buttons' height and texture differences aren't as easy to discern and your fingers have smaller targets to hit from this angle. We got used to it after a few rides but still would have preferred a more natural transition.

In either case, we still want more tactile feedback from the buttons to indicate when a shift has been properly initiated. The exceptionally short button throw is barely a couple of millimeters but the return springs are rather stiff and it's still possible to move the button without actually hitting the contact points in the switch - the clicks are just too light and inaudible. In contrast, the time trial shifters have far more feedback.

Moreover, good luck telling the buttons apart in winter when wearing full-fingered gloves and the inboard button's paddle is surprisingly flexy. Even without a stronger click, stiffening up this small piece would notably improve the feel.

One key ergonomic advantage with Di2, however, is the option for mounting satellite buttons up on the bar tops. On extended climbs, there's no need to shift hand positions out to the hoods when you need a slightly taller or easier gear.

But I don't want to be stranded with a dead battery!

No discussion about Di2 would be complete without addressing the battery life and we're pleased to report that unless you're an exceptionally neglectful rider in terms of maintenance, it's simply not an issue. On average, Shimano says a full charge will last about 1,600km (1,000 miles) but that's heavily dependent on shift frequency - not to mention the number of front versus rear shifts - and other factors such as temperature.

In practice, we've managed roughly 50 percent better than that on our Colorado testing grounds (where the climbs are long but sharp elevation changes relatively infrequent) and even Garmin team mechanics have admitted to only charging their riders' Di2 batteries once during the entire 2,448km-long (1,521 miles) 2009 Giro d'Italia. Not exactly a short-timer.

A blinking LED lets you know when the battery does eventually start to run out of juice. If you choose to ignore the warning for another few rides, front shifts will give out first but you can still muster about 60 more rear shifts before you're totally stuck in your last gear (mind you, we did this part of the test on a repair stand, not out on the road).

High mileage riders will likely only have to charge their Di2 batteries once a month or so and assuming the claimed 500-charge lifespan is valid, most riders will be dead and gone before their battery does the same. Our impression is that Shimano could have comfortably halved the capacity but opted for prudence instead. Total charge time from a completely dead battery is barely over an hour, too.

And what about weather resistance? Each connection is so tight that you need to use the included tool for both installation and removal so as not to damage the wire. Our first test ride in pouring tropical rain turned out to be a good long-term indicator: even when intentionally blasting the bits with a pressure washer, everything still worked just fine.

Installation

Installation for the first-timer will invariably require at least a scan through the included - and very detailed - manual. But aside from some adjustment nuances, the process is mostly familiar and doesn't take much longer than usual.

Wire routing is an obvious difference and there is definitely some creativity required for a clean-looking finished product. Shimano thankfully includes some nifty adhesive cable guides to ease the job and if you're lucky enough to have a mostly black or white frame, they're barely noticeable. Unfortunately there's still a zip-tie required for the down tube-mounted battery holder though.

One quirk about the front derailleur that shouldn't go unmentioned: there's no sensor like on your motorised garage door as to when something's in its way. When installing the derailleur or making adjustments, watch your fingers. Don't worry; the Di2 front derailleur won't cut them off or anything like that but the motor does exert a lot of force so be aware.

What if I crash on it?

The rear derailleur has a built-in 'breakaway' feature whereby the body will essentially separate itself from the motorised internals if you happen to dump the bike on that side. It's not a guarantee against damage but it's a nice insurance policy to have just in case nonetheless (and no, we didn't test it aside from a simulation on the repair stand - it works).

If something slightly more severe occurs, entire components may not always have to be replaced as there are thankfully at least a few small parts available such as pulley cages, brake lever blades, and the like. Otherwise, though, that brings us to our next concern...

Pricing and compatibility

There's no sugarcoating the issue here; Shimano's Dura-Ace Di2 components are horrifically expensive. The rear derailleur alone retails for US$900 - nearly the cost of an entire SRAM Rival group - the front derailleur is only slightly cheaper at US$750, and a pair of shifters fetches US$930. And that's not even including the required wiring harnesses (US$450), the battery (US$100), or its proprietary charger (US$120). Add it up and it's a choice between a fancy Di2 transmission or a decent used car.

Shimano naturally intends Di2 to be filled out with the remaining Dura-Ace 7900 bits and admittedly it seems to work best that way given the brake calipers' modified cable pull ratio and the crankset's ultra-stiff outer chainring. If you're so inclined, other cranksets with standard spacing will work, too, as will other brake calipers though the feel at the lever - and the stopping performance - won't be quite as good.

But no, Di2 won't work with anything out back other than a 10-speed cassette with Shimano spacing (thus including SRAM) and no, we didn't try hacking into the system's 'brain' to make it work with other standards though we'd imagine someone more tech-savvy could probably pull it off.

Wave of the future

Do current cable-actuated systems work, and work well? Yes, absolutely, and better than ever in most cases. But there's also no denying that once you've used Di2, even the best conventional drivetrains suddenly seem a tad clunky in comparison.

Shimano Dura-Ace Di2 is not perfect. There are some ergonomic quirks, it's still not the best option for multiple shifts and it's incredibly expensive. But the level of refinement is also unlike anything else out there and we would offer up the argument that truly innovative developments usually don't come about by playing it safe and maintaining the status quo. It's not a game changer just yet but it just might be once the technology invariably trickles down and prices drop.

Even more interesting, however, is what this could potentially mean for Shimano's off-road line as the benefits of weather resistance and consistent shift performance would apply even more in that arena.

"It absolutely makes sense for other disciplines. We've already got guys who have been racing with it in cyclo-cross and have done well with it," said Shimano US press officer Devin Walton. "It makes a lot of sense for mountain bikes but there are a lot more obstacles on a trail. These parts are a lot more expensive to replace and repair and that's definitely a concern plus the level of potential contamination steps it up a notch. It makes hypothetical sense but to make the jump into real world execution is a whole other issue."

Fair enough, but we're still willing to bet that the next generation of XTR will come with an electronic variant as well. In the meantime, the road version is here already and it's more than well worth a try - as long as you've got the money to do so. Whereas we've been somewhat underwhelmed by Dura-Ace 7900, Di2 has blown us away.

Pros:

Incredibly smooth, precise and reliable shift performance that cable-actuated systems can't match, fantastic lever ergonomics, only a modest weight penalty

Cons:

Incredibly expensive to purchase or replace, slightly more tedious installation, some questionable ergonomics, multiple shift performance could be better

Dual Control shifters, ST-7970 (pair): 258g (US$930)

Rear derailleur, RD-7970: 222g (US$900)

Front derailleur, FD-7970: 120g (US$750)

Battery, SM-BPR1: 70g (US$100)

Upper wiring harness, SM-EW79: 20g (US$170)

Lower wiring harness, SM-EW7970 (short): 81g (US$280)

Battery charger, SM-BCR1: N/A (US$120)