A day in the life of a Tour de France race bike

Following Tyler Farrar’s Felt from dawn to dusk

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

By now, we all have a pretty good idea what riders go through day in and day out at the Tour de France: wake up, breakfast, prepare for the stage, head to the start, sign in, race, head to the next hotel, massage, dinner, sleep, repeat.

But what about the bikes? Just like the riders, there's more to their daily lives than what happens in between the start and finish lines. To find out the rest, we tagged along with the Garmin-Transitions team and followed the primary race bike of sprinter Tyler Farrar from sun-up to sundown on stage 7, five days before he was forced to abandon the race due to earlier injuries.

While it's obvious that the Tour de France is hard on the riders, it's indeed not an easy life for the equipment or the mechanics who care for it all, either.

7:50am: Farrar's Felt F1 Team is safely secured inside the team truck (along with all of the bikes) in front of the team's hotel. The doors are obviously locked but for extra security, Garmin-Transitions staff parks another team car immediately behind so that even if the lock is broken or picked, potential thieves still can't swing the door open.

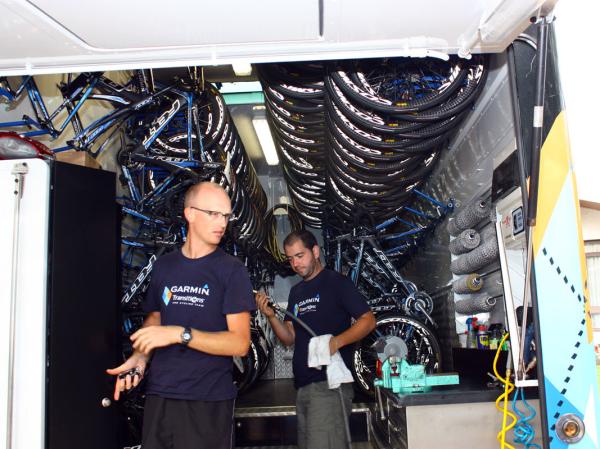

7:55am: After an early breakfast, team mechanics get to work and move the vehicles as needed. The team truck is opened up and all of the team's tyres (complete bikes and spares) are inflated for the day. Bikes are then unloaded, worked on as necessary (though the goal is to have everything completed the night before), and then loaded on to team cars in specific locations depending on that rider's role for the day.

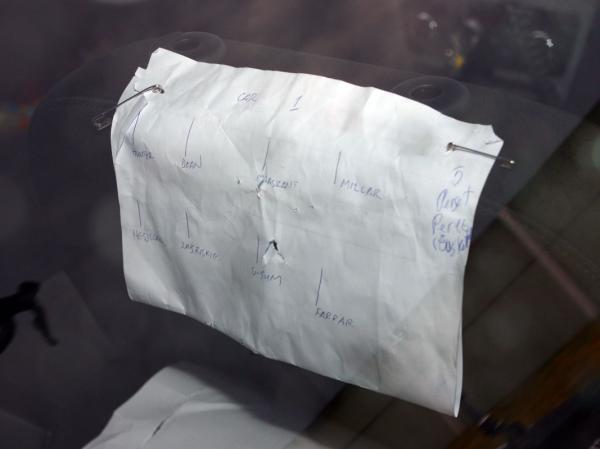

The bikes of the overall team leader and leader for that stage receive the outer right-hand positions while the two most important domestiques for the day get the left-hand outer positions atop the car.

Garmin-Transitions mechanics Kris Withington and Inaki Goiburu start things off by inflating all of the tyres for the day.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

8:30-8:40am: All main and spare bikes and spare wheels are loaded on to all of the team vehicles. Mechanics sort out last-minute details on one or two machines but otherwise, Farrar's and the rest of the team's bikes are ready to go at this point.

8:40am: Team vehicles are moved around yet again and mechanics prepare the insides of the cars for the day's work. Trash from the previous day is cleaned out and spare parts, tools, and wheels are loaded back in. Farrar's race bike sits securely in the meantime on the team car, waiting for the planned 10:45am departure to the stage start.

10:15am: Team vehicles head off for refueling as needed.

10:45am: All riders and staff load into team buses and cars (the service truck heads directly to the hotel for that evening) and depart for the stage start in Tournus.

11:45am: After a bit of a traffic jam (and a convenient police escort through the outskirts of town), buses and cars park in the designated area. Bikes are immediately unloaded and positioned alongside the bus behind a portable barrier.

12:30pm: Farrar exits the team bus, grabs his bike, and then heads to the sign-in area. Afterwards, he returns to the bus for a few more quiet minutes before the racing begins for the day. Once again, the bike lies in wait alongside the bus.

12:50pm: Farrar and the rest of the Garmin-Transitions team re-emerge from the bus, saddle up, then head to the start area.

Tyler Farrar grabs his bike and heads to rider sign-in.

1:00pm: The gun goes off and racing begins!

1:00-5:45pm: Farrar (and his bike) cover 165.5km (102.8mi), including six categorised climbs and three intermediate sprints. At this point of the race, Farrar is mostly trying to recover from severe injuries sustained in stage two and in content to safely roll in in 156th place, 22:17 behind stage winner Sylvain Chavanel (Quick Step).

Farrar's bike has an easier time, finishing with no mechanicals and no crashes.

5:50pm: Farrar arrives back at the team parking area and dismounts his bike before making his way onto the team bus to begin his recovery process while the bike is reloaded onto a team car.

6:30pm: Team vehicles depart to the hotel for the evening, located roughly 45 minutes away just across the border in Chavannes-Debogis. Along the way, an intense thunderstorm erupts and all of the bikes are pelted with rain and hail.

7:45pm: Team vehicles arrive at the hotel. Farrar and the rest of the team, soigneurs, and other staff exit the bus and head in for massages, dinner, and other end-of-day activities. Mechanics begin their post-stage ritual, one bike at a time.

8:35pm: Farrar's bike is finally unloaded from the top of the team car and heads straight to the dedicated washing station for a cleaning. Team mechanic Geoff Brown first spritzes the bike down with a degreasing solution (with extra emphasis on the drivetrain), then cleans the wheels with a soapy sponge.

Second, the drivetrain is thoroughly cleaned with a brush and high-pressure power washer.

The frame, fork, brakes, and other bits are tended to last, again with a soapy sponge and lots of high-pressure water.

A note to readers: Tour bikes are maintained religiously throughout the race, including cable and bearing replacements, on a daily basis. Power washing your own bike is not recommended!

8:40pm: Farrar's bike is washed (yes, it really only took five minutes) and is transferred to the next station where it will be tuned and adjusted as needed.

Inaki Goiburu wasn't satisfied with the rear brake feel so he opted to replace the cable - which took less than two minutes from start to finish.

9:00pm: After patiently waiting its turn in the queue, Farrar's bike is loaded on to a work stand by mechanic Inaki Goiburu, who first starts by drying it with an air gun and is now working solely under artificial lighting. Any remaining water will either corrode steel hardware and/or prevent lubrication from reaching its intended target so Goiburu is particularly diligent with this step.

9:02pm: Tyres and wheels are wiped down and inspected. If needed, a replacement wheel would have been installed at this point (freshly glued tyres need a minimum of 24 hours to cure).

9:03pm: Goiburu dries Farrar's bike further with a dry rag, taking the opportunity to check the frame and other parts for damage.

9:04pm: Goiburu sprays WD-40 into smaller crevices to displace any remaining water, then properly lubes all critical points with oil as necessary, using both a drip bottle and spray can. All bolts are checked for proper torque.

9:06pm: The rear wheel is reinstalled on to Farrar's bike and Goiburu then checks and adjusts the front and rear shifting and rear brake performance.

9:09pm: Goiburu decides the rear brake line is contaminated and begins the replacement process. The cable is clipped in between the housing stops and the ends removed from the brake caliper and brake lever (the latter after first removing the cosmetic cover on the Dura-Ace STI lever).

Interestingly, Goiburu doesn't replace the housing as well but rather purges the internal liner with spray lube.

9:11pm: Goiburu has completed the brake cable replacement, including replacing the cosmetic cap on the lever and crimping an end cap on the cable end.

9:12pm: Goiburu supplements the previously applied chain oil with a layer of grease, applied by hand along the entire length, to seal it in and improve lube durability in the event of rain the following day.

Goiburu then removes the bike from the stand and reinstalls the front wheel, then checks the front brake and headset condition.

9:13pm: Farrar's bike is deemed ready to ride the next day and is loaded back into the team truck.

In total, Farrar's bike has really only received genuine mechanical attention for just 18 minutes – longer than some bike shops take to replace a punctured inner tube. Yet from beginning to end, the day lasted over 13 hours, of which only less than five was spent actually racing.

Bear in mind that like most teams, Garmin-Transitions has several mechanics on simultaneous duty during the Tour de France and short working times such as this are only possible thanks to meticulous assembly to begin with and well-established systems that are put in place by the mechanical staff before the race even begins.

Moreover, crashes will greatly extend this timeline as parts then need to be replaced and repaired.

Farrar was lucky this day – but unfortunately much less so on stage 2, when he and four other team riders crashed heavily, breaking both bodies and bikes. Suffice to say, the mechanics put in a lot more hours that day.